RAIDER

pro

USER’S MANUAL

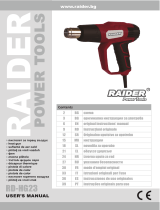

RDP-SHG20

www.raider.bg

Contents

2 BG схема

3 BG оригинална инструкция за употреба

6 EN original instructions’ manual

9 RO Instrucţiuni originale

12 SR Originalno uputstvo za upotrebu

15 MK инструкции

18 SL novodila za uporabo

21 EL οδηγιεσ χρησεωσ

24 HR izvorna upute za rad

27 RU указания безопасности

30 FR mode d’emploi original

33 IT istruzioni originali per l’uso

36 ES instrucciones de uso originales

39 PT instruções originais para uso

○ Пистолет за горещ въздух

aкумулаторен без

батерия и зарядно

○ Pistolj za vreli vazduh

bez baterija i polnaj

○ Фен без батерија и полнач

○ Pistol cu aer cald

○ Fara baterie iI incarcator

○ Decapeur thermique sans

batterie et chargeur

○ Pistola de calor sin bateria

y cargador

○ Pistola de calor sem fio sem

bateria e carregador

○ Pistola di calore senza

batteria e carica batterie

○ Pistolj za vruci zrak bez

baterije i punjaca

○ Vroca zracna pistola brez

baterije in polnilnika

○ Пистолет горячего

воздуха без аккумулятора

и зарядного устройства

Art. No. Item Description

030130 R20 Cordless Drill Li-ion 2 speed 13 mm 44 Nm Solo RDP-SCD20

030220 R20 Cordless Drill Li-ion 2 speed 13 mm 44 Nm Solo RDP-SCD20S

030131 R20 Cordless Hammer Drill-Driver Li-ion 2 speed 13 mm 50Nm Solo

RDP-SCDI20

030217 R20 Cordless Hammer Drill Li-ion 2 speed 13 mm 50Nm Solo

RDP-SCDI20S

030222 R20 Auto touch cordless drill Solo RDP-SCDA20

030159 R20 Brushless cordless draywall screwdriver Solo RDP-SBES20

030132 R20 Cordless Hex Impact Driver Li-ion 1/4" 180 Nm Solo RDP-SHID20

030133 R20 Cordless Impact Wrench Li-ion 1/2" 250 Nm Solo RDP-SCIW20

030134 R20 Cordless Impact Wrench Li-ion 1/2" 400 Nm 5 speed Solo

RDP-SCIW20-5

030221 R20 Cordless Impact Wrench Li-ion 1/2” 400 Nm 5 speed Solo

RDP-SCIW20S

030151 R20 Cordless Rotary Hammer Brushless Li-ion SDS-plus Solo RDP-

SBRH20

030135 R20 Cordless Rotary Hammer Li-ion SDS-plus Solo RDP-SRH20

030136 R20 Cordless Angle Grinder Li-ion Ø125mm 10000min-1 Solo RDP-SBAG20

030223 R20 Brushless Cordless Angle Grinder Li-ion Ø125mm 11500min-1 Solo

RDP-SBAG20S

Art. No. Item Description

030152 R20 Cordless Mixer Li-ion Solo RDP-SHM20

030137 R20 Cordless Jig Saw Li-ion quick 80mm Solo RDP-SJS20

030138 R20 Cordless Reciprocating Saw Li-ion quick Solo RDP-SRS20

030139 R20 Cordless Circular Saw Li-ion Ø165x20 mm 24T 4200 min-1 laser Solo

RDP-SCS20

163143 Circular Saw Blade Tungsten Carbide Tipped Ø165x20 mm 24T

030140 R20 Cordless Random Orbit Sander Li-ion Ø125 mm variable speed Solo

RDP-SRSA20

030141 R20 Cordless Multi-Tool Li-ion 3° variable speed quick Solo RDP-SOMT20

030154 R20 Cordless Glue gun Li-ion ø11 Solo RDP-SGLG20

030160 R20 Cordless heat gun Li-ion Solo RDP-SHG20

030153 R20 Cordless stapler comb Li-ion Solo RDP-SST20

074202 R20 Пистолет за боя акум. Li-ion Ø1.5 1.8 2.2 mm 1 L Solo RDP-SSGC20

039706 R20 Adapter USD with lamp for series RDP-R20 System

075328 R20 Lawn mower Li-ion 360 mm 35L Solo RDP-SLM20

Art. No. Item Description

075711 R20 Cordless brush cutter with blade and trimmer head detachable shaft

RDP-SBBC20 Set

075712 Pole saw head tube for RDP-SBBC20

075713 Hedge trimmer head with tube for RDP-SBBC20

075545 R20 Cordless trimmer Li-ion 300 mm Solo RDP-SCBC20

075707 R20 Cordless headge trimmer Li-ion 510 mm Solo RDP-SCHT20

075708 R20 Cordless pole saw Li-ion 510 mm set RDP-SPS20

075710 R20 Cordless chain saw Li-ion 200 mm solo RDP-SCS20

030155 R20 Cordless chain saw brushless 350 mm (14") Solo RDR-SBCS20

090319 R20 Cordless wet and dry cleaner Solo RDR-SDWC20

090320 R20 Ash cleaner Solo RDR-SWC20

030211 Cordless Drill Li-ion 2 speed 13 mm 44 Nm 20 V 1.5 Ah 1 h RDP-SCD20 Set

030219 Cordless Drill Li-ion 2 speed 13 mm 44 Nm 20 V 1.5 Ah 1 h RDP-SCD20S

Set

030215 R20 Brushless cordless drill Set RDP-SBCDA20 Set

030208 Cordless Hammer Drill-Driver Li-ion 2 speed 13mm 50Nm 20 V 2x2 Ah 1 h in

Case RDP-SCDI20 Set

030216 Cordless Hammer Drill Li-ion 2 speed 13mm 50Nm 20 V 2x2 Ah 1 h in Case

RDP-SCDI20S Set

Art. No. Item Description

030209 Cordless Angle Grinder Li-ion Ø125mm 10000min-1 20 V 2 Ah 1 h in Case

RDP-SBAG20 Set

030224 R20 Brushless Cordless Angle Grinder Li-ion Ø125mm 11500min-1 Sет

RDP-SBAG20S

030210 Cordless Jig Saw Li-ion quick 80mm 20 V 2 Ah 1 h in Case RDP-SJS20 Set

075709 R20 Cordless chain saw Li-ion 200 mm set RDP-SCS20

090315 R20 Ash cleaner Set RDR-SWC20

032120 R20 System Starter Kit Li-ion 2 Ah 1h for series RDP-R20 System

131110 R20 Battery Pack Li-ion 20 V 1.5 Ah for series RDP-R20 System

131152 R20 Battery Pack Li-ion 20 V 2 Ah for series RDP-R20 System

131153 R20 Battery Pack Li-ion 20 V 4 Ah for series RDP-R20 System

131157 R20 Батерия Li-ion 20 V 6 Ah за серията RDP-R20 System

039703 R20 Battery and Charger for series RDP-R20 System

039704 R20 Rapid Charger for series RDP-R20 System

039707 R20 Dual Charger for series RDP-R20 System 2x3 A

6www.raider.bg

ИЗОБРАЗЕНИ ЕЛЕМЕНТИ

1. Изходяща дюза.

2. Пусков прекъсвач - трипозиционен:

0 - Пистолета е изключен;

1 - Студен въздух - продухване със

студен въздух за бързо охлаждане на

дюзата и охлаждане на нагревателя;

2 - Топъл въздух

3. Ръкохватка.

4. Кръгла дюза

5. Рефлекторна дюза

6. Повърхностна дюза

ELEMENTS DEPICTED

1. Output nozzle.

2. Trigger - 3 modes:

0 - The gun is turned o;

1 - Cold air - blowing with cold air for

fast cooling of the nozzle and cooling of

the heater;

2 - Hot air

3. Handle.

4. Concentration nozzle

5. Spoon shaped reecting nozzle

6. Surface nozzle

2

1

3

Прочетете ръководството преди употреба!

Refer to instruction manual / booklet!

Носете защитни антифони!

Always wear hearing protection!

Носете защитна маска!

Wear dust mask!

Носете защитни очила!

Wear safety glases!

НЕ СЪДЪРЖА БАТЕРИЯ И ЗАРЯДНО!

BATTERY AND CHARGER NOT INCLUDED!

4

5

6

7

ОРИГИНАЛНА ИНСТРУКЦИЯ ЗА УПОТРЕБА

Уважаеми потребители,

Поздравления за покупката на машина от най-бързоразвиващата се марка

за електрически и пневматични инструменти - RAIDER. При правилно инсталиране и

експлоатация, RAIDER са сигурни и надеждни машини и работата с тях ще Ви достави

истинско удоволствие. За Вашето удобство е изградена и отлична сервизна мрежа с 40

сервиза в цялата страна.

Преди да използвате тази машина, моля, внимателно се запознайте с настоящата

“Инструкция за употреба”.

В интерес на Вашата безопасност и с цел осигуряване на правилната й

употреба, прочетете настоящите инструкции внимателно, включително препоръките

и предупрежденията в тях. За избягване на ненужни грешки и инциденти, важно е тези

инструкции да останат на разположение за бъдещи справки на всички, които ще ползват

машината. Ако я продадете на нов собственик то “Инструкцията за употреба” трябва да

се предаде заедно с нея, за да може новия ползвател да се запознае със съответните

мерки за безопасност и инструкциите за работа.

“Евромастер Импорт Експорт” ООД е упълномощен представител на

производителя и собственик на търговската марка RAIDER. Адресът на управление на

фирмата е гр. София 1231, бул. “Ломско шосе” 246, тел. 0700 44 155, 934 10 10, www.raider.

bg; www.euromasterbg.com; e-mail: info@ euromasterbg.com.

От 2006 година във фирмата е въведена системата за управление на

качеството ISO 9001:2008 с обхват на сертификацията: Търговия, внос, износ и сервиз

на професионални и хоби електрически, пневматични и механични инструменти и обща

железария. Сертификатът е издаден от Moody International Certication Ltd, England.

ТЕХНИЧЕСКИ ДАННИ

параметър мерна

единица стойност

Модел -RDP-SHG20

Напрежение V 20

Температура на изхода ˚C 450

Температура на изхода с кръгла дюза ˚C 550

Дебит на въздуха l/min 200

Скорост на въздуха m/s 15

Ниво на звукова мощност по-малко от dB(А) 70

BG

8www.raider.bg

1. Общи указания за безопасна работа.

Прочетете внимателно всички указания. Неспазването на приведените по-долу

указания може да доведе до токов удар, пожар и/или тежки травми. Съхранявайте тези

указания на сигурно място.

1.1. Не използвайте машината във влажна среда.

1.2. В случай на повреда, ремонтните работи трябва да се извършват само от

специалист.

1.3. Бъдете внимателни при употреба около места със запалими вещества. Не

прилагайте горещия въздух на едно място за продължително време.

1.4. Винаги проверявайте дали работното място е добре проветрено. Не използвайте

машината като сешоар.

2. Безопасен начин на работа.

2.1. Опасност от поява на пламъци!

2.2. Не докосвайте горещата дюза (1).

2.3. Носете защитни ръкавици.

2.4. Поставете машината на стойка и я оставете да се охлади преди да я приберете.

Дръжте машината и консумативите към нея извън обсега на деца.

2.5. Ако дюзата на машината е нагорещена и искате да освободите и двете си ръце за

работа, може да издърпате подпората на стойката и да поставите машината в изправена

позиция на нейната основа.

2.6. Никога не насочвайте горещия въздух към хора или животни.

2.7. Опасност от пожари и експлозии! При работа топлината може да се пренесе към

повърхности извън полезрението. Могат да се появят запалими и отровни газове при

работа с пластмаси, бои (особено по-стари), лакове и подобни материали. Не използвайте

машината в близост до силно възпламеними газове или материали. Не дръжте дюзата

много близо до работната повърхност. Използвайте само оригинални консумативи. Не

всички описани консумативи са включени в стандартната опаковка.

4. Включване.

4.1. Машината трябва да е в изключено положение, преди свързване към захранването.

4.2. Поставете пусковия прекъсвач (2) в позиция 2, за топъл въздушен поток.

Желателно e да държите машината на по-голямо разстояние от работната повърхност.

Разстоянието между дюзата и обработвания обект зависи от естеството на материала.

Поставете пусковия прекъсвач (2) в позиция 1, за студен въздушен поток.

При „студено обдухване“, инструментът работи в режим на нагнетяване на въздуха

без подгряване. При необходимост от постоянно охлаждане на материалите (например,

при изпълнение на заваръчни работи) трябва да се има предвид наличието на такава

опция.

Студената степен за бързо охлаждане на инструмента удължава живота на пистолета

за горещ въздух. Можете да охлаждате повърхности и материали след обработка. Само

вентилатора работи при студена степен; нагревателят се изключва.

5. Начин на работа и приложение.

5.1. Отстраняване на боя. Поставете плоската дюза. Нагрейте до размекване боята и

я отстранете използвайки шпакла. Не нагрявайте боята твърде дълго, защото това ще

овъгли боята и ще доведе до по-трудното и отстраняване. Много лепила (напр. стикери)

омекват при нагряване, позволявайки на слепените повърхности да бъдат разделени и

втечненото лепило да бъде отстранено.

5.2. Отстраняване на боя от прозорци. Стъклото е чупливо. Винаги използвайте дюзата

предвидена за стъкло. От вертикални повърхности боята може да бъде отстранена с

шпакла или мека телена четка.

5.3. Оформяне на пластмасови тръби. Поставете рефлекторната дюза. За да избегнете

поврежданото на тръбите, напълнете с пясък от двете страни и запушете и двата края.

Нагрявайте тръбата постепенно като придвижвате пистолета от край до край.

5.4. Оцветяване на дърво.

Поставете плоската дюза. Оцветяването с горещ въздух придава на дървото ръждив

9

оттенък. Не дръжте дюзата твърде близо до дървото, защото това ще го оцвети

неравномерно. Внимателно отстранете всякакви грапавини и стърготини с фина шкурка.

5.5. Работа с термосвиваем шлаух. Подберете подходящия накрайник за пистолета от

окомплектовката - нагрявайте термосвиваемия шлаух равномерно.

5.6. Размразяване на тръби. Не опитвайте да размразявате РVС тръби. Поставете

рефлекторната дюза. Винаги нагрявайте замръзналата площ в посока отвън-навътре.

(от краищата към центъра). Забележка: Тръбите за вода често са трудно различими от

тръбите за газ. Медните тръби са съединени посредством калай и поради това не трябва

да се нагряват над 200°С.

6. Съхранение и поддръжка. Винаги изключвайте захранващия кабел от контакта

преди да поставите някой от аксесоарите. Винаги пазете вентилационните отвори

открити и чисти.

7. Информация за акумулаторната батерия и зарядното устройство.

Акумулаторната машина се доставя без батерия и зарядно. Използвайте само батерия и

зарядно от серията R20 System.

8. Опазване на околната среда. С оглед опазване на околната среда

електроинструментът, допълнителните приспособления и опаковката трябва да бъдат

подложени на подходяща преработка за повторното използване на съдържащите се в

тях суровини. Не изхвърляйте електроинструменти при битовите отпадъци! Съгласно

Директивата на ЕС 2012/19/EC относно излезлите от употреба електрически и електронни

устройства и утвърждаването й като национален закон електроинструментите, които не

могат да се използват повече, трябва да се събират отделно и да бъдат подлагани на

подходяща преработка за оползотворяване на съдържащите се в тях вторични суровини.

10 www.raider.bg

ORIGINAL INSTRUCTIONS MANUAL

Dear Customer,

Congratulations on the purchase of machinery from the fastest growing brand of electric

and pneumatic tools - RAIDER. When properly installed and operating, RAIDER are safe and

reliable machines and work with them will deliver a real pleasure. For your convenience has

been built and excellent service network of 40 service station across the country.

Before using this machine, please carefully acquainted with these “instructions for use.

In the interest of your safety and to ensure proper use and read these instructions carefully,

including the recommendations and warnings in them. To avoid unnecessary errors and

accidents, it is important that these instructions will remain available for future reference to all

who will use the machine. If you sell it to a new owner “Instructions for Use” must be submitted

along with it to enable new users to become familiar with relevant safety and operating

instructions.

Euromaster Import Export Ltd. is an authorized representative of the manufacturer and

owner of the trademark RAIDER.

Adress: Soa City 1231, Bulgaria “Lomsko shausse” Blvd. 246, tel +359 700 44 155, 934 10

10, www.raider.bg; www.euromasterbg.com; e-mail: [email protected].

Since 2006 the company introduced the system of quality management ISO 9001:2008 with

scope of certication: Trade, import, export and servicing of hobby and professional electrical,

mechanical and pneumatic tools and general hardware. The certicate was issued by Moody

International Certication Ltd, England.

TECHNICAL DATA

parameter unit value

Model -RDP-SHG20

Voltage V 20

Temperature at the nozzle outlet ˚C 450

Temperature at the concentration nozzle outlet ˚C 550

Air volume l/min 200

Air ow m/s 15

Sound power level is lower than dB(А) 70

EN

11

1. General instructions for safe work.

Read all instructions carefully. Failure to follow the instructions below may result in electric

shock, re, and / or serious injury. Keep these instructions in a safe place.

1.1. Do not use the machine in a humid environment.

1.2. In the event of a fault, repair work must only be carried out by a specialist.

1.3. Be careful when using around ammable places. Do not apply hot air in one place for

a long time.

1.4. Always check that the workplace is well ventilated. Do not use the machine as a hair

dryer.

2. Safe way of work.

2.1. Danger of ames!

2.2. Do not touch the hot nozzle (1).

2.3. Wear protective gloves.

2.4. Place the machine on a stand and allow it to cool before storing it. Keep the machine

and its supplies out of the reach of children.

2.5. If the machine nozzle is hot and you want to release both hands for work, you can pull

out the stand support and place the machine in an upright position on its base.

2.6. Never direct hot air at people or animals.

2.7. Danger of re and explosion! During operation, heat can be transferred to surfaces out

of sight. Flammable and toxic gases may occur when working with plastics, paints (especially

older ones), varnishes and similar materials. Do not use the machine near ammable gases or

materials. Do not keep the nozzle very close to the work surface. Use only original consumables.

Not all of the consumables described are included in the standard packaging.

4. Inclusion.

4.1. The machine must be in the o position before connecting to the power supply.

4.2. Set the start switch (2) to position 2 for warm airow.

It is advisable to keep the machine at a greater distance from the work surface.

The distance between the nozzle and the workpiece depends on the nature of the material.

Set the start switch (2) to position 1 for cold air ow.

In “cold blowing”, the tool operates in air injection mode without heating. If constant cooling

of the materials is required (for example, when performing welding work), the presence of such

an option must be taken into account.

A cold degree of rapid cooling of the tool extends the life of the hot air gun. You can cool

surfaces and materials after treatment. Only the fan runs in cold mode; the heater switches o.

5. Mode of operation and application.

5.1. Paint removal. Install the at nozzle. Heat the paint until soft and remove it using a

spatula. Do not heat the paint for too long, as this will char the paint and make it more dicult

to remove. Many adhesives (eg stickers) soften when heated, allowing the bonded surfaces to

separate and the liqueed adhesive to be removed.

5.2. Paint removal from windows. The glass is brittle. Always use the nozzle provided for

glass. From vertical surfaces the paint can be removed with a spatula or a soft wire brush.

5.3. Forming of plastic pipes. Install the reector nozzle. To avoid damaging the pipes, ll

with sand on both sides and plug both ends. Heat the barrel gradually as you move the gun

from end to end.

5.4. Staining of wood.

Install the at nozzle. Staining with hot air gives the wood a rusty hue. Do not keep the

nozzle too close to the tree, as this will stain it unevenly. Carefully remove any roughness and

sawdust with ne sandpaper.

5.5. Work with heat-shrinkable hose. Select the appropriate gun nozzle from the kit - heat the

heat-shrinkable hose evenly.

5.6. Defrosting of pipes. Do not attempt to defrost PVC pipes. Install the reector nozzle.

Always heat the frozen area from outside to inside. (from the edges to the center). Note: Water

pipes are often dicult to distinguish from gas pipes. The copper pipes are connected by

means of tin and therefore should not be heated above 200 ° C.

6. Storage and maintenance. Always unplug the power cord before inserting any of the

12 www.raider.bg

accessories. Always keep the ventilation openings open and clean.

7. Battery and charger information.

The battery machine is delivered without battery and charger. Use only the R20 System battery

and charger.

8. Environmental protection. In order to protect the environment, the power tool, accessories

and packaging must be properly recycled for the reuse of the raw materials they contain. Do

not dispose of power tools with household waste! According to EU Directive 2012/19 / EC on

end-of-life electrical and electronic devices and its adoption as national law, power tools that

can no longer be used must be collected separately and subjected to appropriate processing

to utilize the contained in them secondary raw materials.

13

Instrucţiuni originale

Dragi utilizatori,

Felicitări pentru achiziţionarea unui suantă de aer cald marca cu cel mai mare

succes de pe piaţă - Raider. Atunci când sunt instalate şi gata de operare, RAIDER sunt cele

mai sigure şi abile maşini şi lucrand cu ele va o adevarata placere. Pentru confortul dvs. a

fost construita şi elaborata o reţea de servicii excelente si centre de service din întreaga ţară.

Înainte de a utiliza suantă de aer cald, vă rugăm să va familiarizati cu atenţiein legatura cu

aceste instrucţiuni “pentru utilizare.

În interesul siguranţei dumneavoastră şi pentru a asigura utilizarea corespunzătoare

a acestuia, citiţi cu atenţie aceste instrucţiuni, inclusiv recomandările şi avertizările din ele.

Pentru a evita erorile de folosire inutile şi accidentele, este important ca aceste instrucţiuni sa

rămâna disponibile pentru referinţe ulterioare tuturor celor care vor utiliza cricul. Dacă revindeti

unui nou proprietar “Instrucţiunile de utilizare”, trebuie să e prezentate împreună cu el pentru

a permite utilizatorilor noi să se familiarizeze cu instructiunile de siguranţă şi instrucţiunile de

operare.

RAIDER marca exclusiva a societăţii EUROMASTER Import Export SRL, Soa 1231,

“Lomsko shosse 246, tel +359 700 44 155, 934 10 10, www.raider.bg; www.euromasterbg.com,

e-mail: info @ euromasterbg. com.

Din anul 2006, compania a introdus sistemul de management al calitatii ISO

9001:2008, cu domeniul de aplicare al certicare: Comert, importul, exportul şi service-hobby şi

profesionale unelte electrice, mecanice şi pneumatice şi hardware-ul în general. A fost eliberat

certicatul de Moody International Certication Ltd., England.

Detalii tehnice

Parametrii Unitate Valoare

Model -RDP-SHG20

Voltaj V 20

Temperatura la ieșirea duzei ˚C 350

Temperatura la ieșirea duzei de concentrație ˚C 550

Volumul de aer l/min 300

Flux de aer l/min 500

Nivelul de putere sonoră este mai mic decât dB(А) 70

ELEMENTE DEPICATE

1. Duza de ieșire.

2. Declanșator - 3 moduri:

0 - Pistolul este oprit;

1 - Aer rece - suare cu aer rece pentru răcirea rapidă a duzei și răcirea încălzitorului;

2 - Aer cald

3. mâner.

4. Duza de concentrare

5. Duză reectantă în formă de lingură

6. Duză de suprafață

RO

14 www.raider.bg

1. Instrucțiuni generale pentru o muncă sigură.

Citiți cu atenție toate instrucțiunile. Nerespectarea instrucțiunilor de mai jos poate duce la șoc

electric, incendiu și / sau vătămări grave. Păstrați aceste instrucțiuni într-un loc sigur.

1.1. Nu folosiți mașina într-un mediu umed.

1.2. În cazul unei defecțiuni, lucrările de reparație trebuie efectuate numai de un specialist.

1.3. Aveți grijă când utilizați în jurul locurilor inamabile. Nu aplicați aer cald într-un singur loc

pentru o lungă perioadă de timp.

1.4. Vericați întotdeauna dacă locul de muncă este bine ventilat. Nu folosiți mașina ca uscător

de păr.

2. Mod de lucru sigur.

2.1. Pericol de ăcări!

2.2. Nu atingeți duza erbinte (1).

2.3. Purtați mănuși de protecție.

2.4. Puneți mașina pe un suport și lăsați-o să se răcească înainte de a o depozita. Nu lăsați

aparatul și consumabilele sale la îndemâna copiilor.

2.5. Dacă duza mașinii este erbinte și doriți să eliberați ambele mâini pentru muncă, puteți

scoate suportul suportului și așezați mașina într-o poziție verticală pe baza sa.

2.6. Nu direcționați niciodată aerul cald către oameni sau animale.

2.7. Pericol de incendiu și explozie! În timpul funcționării, căldura poate transferată pe

suprafețe la vedere. Gazele inamabile și toxice pot apărea atunci când lucrați cu materiale

plastice, vopsele (în special cele mai vechi), lacuri și materiale similare. Nu folosiți mașina în

apropierea de gaze sau materiale inamabile. Nu țineți duza foarte aproape de suprafața de

lucru. Folosiți numai consumabile originale. Nu toate consumabilele descrise sunt incluse în

ambalajul standard.

4. Includerea.

4.1. Mașina trebuie să e în poziție oprită înainte de conectarea la sursa de alimentare.

4.2. Setați întrerupătorul de pornire (2) pe poziția 2 pentru uxul de aer cald.

Este recomandabil să păstrați mașina la o distanță mai mare de suprafața de lucru.

Distanța dintre duză și piesa de prelucrat depinde de natura materialului.

Setați întrerupătorul de pornire (2) pe poziția 1 pentru uxul de aer rece.

În „suare la rece”, instrumentul funcționează în modul de injecție de aer fără încălzire. Dacă

este necesară o răcire constantă a materialelor (de exemplu, la efectuarea lucrărilor de sudare),

trebuie să se țină seama de prezența unei astfel de opțiuni.

Un grad rece de răcire rapidă a sculei prelungește durata de viață a pistolului cu aer cald. Puteți

răci suprafețele și materialele după tratament. Doar ventilatorul funcționează în modul rece;

încălzitorul se oprește.

5. Mod de operare și aplicare.

5.1. Îndepărtarea vopselelor. Instalați duza plată. Încălziți vopseaua până se moale și

îndepărtați-o folosind o spatulă. Nu încălziți vopseaua prea mult timp, deoarece acest lucru

va încărca vopseaua și va îngreuna eliminarea. Mulți adezivi (de ex. Autocolante) se înmoaie

atunci când sunt încălziți, permițând separarea suprafețelor lipite și adezivul licheat.

5.2. Îndepărtarea vopselelor de la ferestre. Paharul este casant. Folosiți întotdeauna duza

prevăzută pentru sticlă. Din suprafețe verticale vopseaua poate îndepărtată cu o spatulă sau

o perie de sârmă moale.

5.3. Formarea conductelor de plastic. Instalați duza reectorului. Pentru a evita deteriorarea

conductelor, umpleți cu nisip pe ambele părți și conectați ambele capete. Încălziți butoiul

treptat în timp ce deplasați arma de la capăt la capăt.

5.4. Pata de lemn.

Instalați duza plată. Pătrunderea cu aer cald oferă lemnului o nuanță ruginită. Nu țineți duza

prea aproape de copac, deoarece aceasta o va păta neuniform. Îndepărtați cu grijă orice

rugozitate și rumeguș cu șmirghel n.

5.5. Lucrați cu furtun termorezistent. Selectați duza adecvată a pistolului din kit - încălziți

uniform furtunul termocontractabil.

5.6. Dezghetarea conductelor. Nu încercați să dezghețați conductele din PVC. Instalați duza

15

reectorului. Încălziți întotdeauna zona înghețată de la exterior la interior. (de la margini la

centru). Notă: Adesea, conductele de apă sunt greu de diferențiat de conductele de gaz. Țevile

de cupru sunt conectate cu staniu și, prin urmare, nu trebuie încălzite peste 200 ° C.

6. Depozitare și întreținere. Deconectați întotdeauna cablul de alimentare înainte de a introduce

oricare dintre accesorii. Mențineți întotdeauna deschiderile de ventilație deschise și curate.

7. Informații despre baterie și încărcător.

Mașina cu baterii este livrată fără baterie și încărcător. Folosiți numai acumulatorul și încărcătorul R20

System.

8. Protecția mediului. Pentru a proteja mediul înconjurător, scula electrică, accesoriile și

ambalajele trebuie reciclate corespunzător pentru reutilizarea materiilor prime pe care le

conțin. Nu aruncați uneltele electrice cu deșeurile menajere! Conform Directivei UE 2012/19

/ CE privind dispozitivele electrice și electronice de sfârșit de viață și adoptarea acesteia ca

legislație națională, instrumentele electrice care nu mai pot utilizate trebuie colectate separat

și supuse unei prelucrări corespunzătoare pentru a utiliza conținutul în ele secundare. materie

prima.

16 www.raider.bg

Originalno uputstvo za upotrebu

Poštovani kupci,

Hvala što ste kupili mašinu marke RAIDER, marka koja se naj brže razvija u oblasti

električnih i pneumatskih instrumenata. Pri pravilnom instaliranju i korišćenju, RAIDER su

sigurne i stabilne mašine, tako da će Vam rad s njima, predstavljati zadovoljstvo. Zbog Vaše

sigurnosti izgrađena je i odlična servisna mreža, s 36 servisa u celoj zemlji.

Pre početka korišćenja pištolja za vreli vazduh, molimo Vas, pažljivo pročitajte postojeće

‘’Instrukcije za upotrebu’’.

Zbog Vaše bezbednosti i u cilju pravilne upotrebe, pažljivo pročitajte postojeće

instrukcije, posebno preporuke i upozorenja. Da bi izbegli nepotrebne greške i incidente, važno

je da ove instrukcije budu na raspolaganju svim korisnicima mašine. Ako mašinu prodate

drugom licu, obavezno mu dostavite, uz nju i ‘’Instrukcije za upotrebu’’, kako bi se novi korisnik

upoznao s postojećim merama za bezbednost, kao i s instrukcijama za rad.

Isključivi predstavnik RAIDER-a je rma ‘’Euromaster Import Eksport’’ OOD, grad Soja 1231,

bul. ‘’Lomsko šose’’ 246, tel. +359 700 44 155, 934 10 10, www.raider.bg; www.euromasterbg.

com; e-mail: info@ euromasterbg.com.

Od 2006-te godine rma poseduje sertikat za upravljanje kvalitetom ISO 9001:2008

sa sertikatima za: Trgovinu, uvoz, izvoz i servis profesionalnih i malih električnih, pneumatskih

i mehaničkih instrumenata i opšte gvožđurije. Sertikat je izdat od strane Moody International

Certication Ltd, England.

TEHNIČKE KARAKTERISTIKE

Parametar Jedinica

mera Vrenost

Model -RDP-SHG20

Nominalni napon V 20

Temperatura na izlazu sa mlaznice ˚C 350

Temperatura na izlazu iz mlaznice za koncentraciju ˚C 550

Zapremina vazduha l/min 300

Protok vazduha l/min 500

Nivo zvučne snage je niži od dB(А) 70

ODRŽANI ELEMENTI

1. Izlazna mlaznica.

2. Okidač - 3 režima:

0 - pištolj je isključen;

1 - Hladni vazduh - duvanje hladnim vazduhom za brzo hlađenje mlaznice i hlađenje grejača;

2 - vrući vazduh

3. Ručka.

4. Mlaznica za koncentraciju

5. Žličica u obliku kašike u obliku kašike

6. Površinska mlaznica

1. Opšta uputstva za bezbedan rad.

Pažljivo pročitajte sva uputstva. Nepoštovanje sledećih uputstava može dovesti do strujnog

udara, požara i / ili ozbiljnih povreda. Ova uputstva čuvajte na sigurnom mestu.

SR

17

1.1. Ne koristite mašinu u vlažnom okruženju.

1.2. U slučaju kvara, popravke mora da obavlja samo stručnjak.

1.3. Budite pažljivi kada koristite oko zapaljivih mesta. Ne nanosite vruć vazduh na jedno

mesto duže vreme.

1.4. Uvek proverite da li je radno mesto dobro provetreno. Ne koristite mašinu kao sušilo

za kosu.

2. Siguran način rada.

2.1. Opasnost od plamena!

2.2. Ne dirajte vruću mlaznicu (1).

2.3. Nosite zaštitne rukavice.

2.4. Postavite mašinu na postolje i ostavite je da se ohladi pre nego što je odložite. Čuvajte

mašinu i zalihe van dosega dece.

2.5. Ako je mlaznica mašine vruća i želite da pustite obe ruke za rad, možete izvući nosač

postolja i postaviti uređaj u uspravan položaj na njegovoj osnovi.

2.6. Nikada ne usmeravajte vruć vazduh na ljude ili životinje.

2.7. Opasnost od požara i eksplozije! U toku rada toplota se može prenijeti na površine izvan

vidokruga. Zapaljivi i toksični gasovi mogu se pojaviti pri radu sa plastikom, bojama (posebno

starijim), lakovima i sličnim materijalima. Ne koristite mašinu u blizini zapaljivih gasova

ili materijala. Mlaznicu ne držite blizu radne površine. Koristite samo originalne potrošne

materijale. Nisu svi opisani potrošni materijali uključeni u standardno pakovanje.

4. Uključenost.

4.1. Mašina mora biti u isključenom položaju pre nego što se priključi na napajanje.

4.2. Podesite prekidač za pokretanje (2) u položaj 2 za topli protok vazduha.

Preporučljivo je držati mašinu na većoj udaljenosti od radne površine.

Razmak između mlaznice i obratka zavisi od prirode materijala.

Podesite prekidač za pokretanje (2) u položaj 1 za protok hladnog vazduha.

U “hladnom puhanju”, alat radi u režimu ubrizgavanja vazduha bez zagrevanja. Ako je

potrebno stalno hlađenje materijala (na primer, pri izvođenju zavarivačkih radova), prisustvo

takve opcije mora se uzeti u obzir.

Hladan stepen brzog hlađenja alata produžava život pištolja za topli vazduh. Nakon tretmana

možete hladiti površine i materijale. Samo ventilator radi u hladnom režimu; grejač se isključuje.

5. Način rada i primene.

5.1. Uklanjanje boje. Ugradite ravnu mlaznicu. Zagrevajte boju do meke i uklonite je

lopaticom. Ne zagrevajte boju predugo, jer će je obojati boja i otežati uklanjanje. Mnogo lepila

(npr. Nalepnice) omekšavaju se kada se zagreju, omogućujući odlepljenim površinama da se

odvoje, a utečeni lepak ukloni.

5.2. Uklanjanje boje sa prozora. Čaša je krhka. Uvek koristite mlaznicu predviđenu za staklo.

Sa vertikalnih površina boja se može ukloniti lopaticom ili mekom žičanom četkom.

5.3. Formiranje plastičnih cevi. Ugradite mlaznicu reektora. Da ne biste oštetili cevi,

napunite ih peskom sa obe strane i zakačite oba kraja. Zagrevajte cev postepeno dok pomerate

pištolj od kraja do kraja.

5.4. Bojenje drveta.

Ugradite ravnu mlaznicu. Bojenje vrućim vazduhom daje drvu rđastu nijansu. Mlaznicu ne

držite preblizu stablu, jer ćete je tako neravnomerno obojiti. Pažljivo uklonite sve hrapavosti i

piljevinu nim brusnim papirom.

5.5. Radite sa crevom za skupljanje toplote. Izaberite odgovarajuću mlaznicu pištolja iz

kompleta - ravnomerno zagrejte crevo koje se može skupiti.

5.6. Odmrzavanje cevi. Ne pokušavajte odmrzavati PVC cevi. Ugradite mlaznicu reektora.

Uvek grejte smrznuto područje od spolja do unutra. (od ivica do centra). Napomena: Vodovodne

cevi je često teško razlikovati od gasnih cevi. Bakrene cevi su povezane kositrom i zato ih ne

treba zagrevati iznad 200 ° C.

6. Skladištenje i održavanje. Uvek isključite kabl za napajanje pre stavljanja bilo koje dodatne

opreme. Otvore za ventilaciju uvek držite otvorene i čiste.

7. Informacije o bateriji i punjaču.

18 www.raider.bg

Baterija se isporučuje bez baterije i punjača. Koristite samo bateriju i punjač sistema R20.

8. Zaštita životne sredine. Da bi zaštitili životnu sredinu, električni alat, pribor i ambalaža

moraju se pravilno reciklirati radi ponovne upotrebe sirovina koje sadrže. Ne odlažite električni

alat zajedno sa kućnim otpadom! Prema Direktivi EU 2012/19 / EZ o istrošenim električnim i

elektronskim uređajima i njenom usvajanju kao nacionalnim zakonom, električni alati koji se

više ne mogu koristiti moraju se sakupljati odvojeno i podvrgnuti odgovarajućoj obradi kako bi

se iskoristili sadržani u njima sekundarni sirovine.

19

ОРИГИНАЛНO УПАТСТВО ЗА УПОТРЕБА

Почитувани корисници,

Честитки за купување на машина од бързоразвиващата се бренд за електрични и

пневматски алатки - RAIDER. При правилно инсталирање и работа, RAIDER се сигурни и

доверливи машини и работата со нив ќе ви овозможи вистинско задоволство. За Вашето

погодност е изградена и одличната сервисна мрежа.

Пред да ја користите оваа машина, ве молиме внимателно запознајте со оваа

“Упатствата за употреба”.

Во интерес на Вашата безбедност и со цел да се обезбеди правилна и употреба,

прочитајте ги упатствата внимателно, вклучувајќи препораките и предупредувањата во

нив. За избегнување на непотребни грешки и инциденти, важно е овие инструкции да

останат на расподложкагање за идните извештаи на сите кои ќе ги користат машината. Ако

ја продадете на нов сопственик тоа “Упатствата за употреба” треба да се предаде заедно

со неа, за да може новиот корисник да се запознае со соодветни мерки за безбедност и

упатствата за работа.

“Евромастер Импорт Експорт” ООД е овластен претставник на производителот и

сопственик на трговската марка RAIDER. Адресата на управување на компанијата е

Софија 1231, бул “Ломско улица” 246, тел +359 700 44 155, 934 10 10, www.raider.bg; www.

euromasterbg.com; e-mail: info @ euromasterbg. com

Од 2006 година во компанијата е воведен системот за управување со квалитетот ISO

9001:2008 со опсег на сертификација: Трговија, увоз, извоз и сервис на професионални и

хоби електрични, пневматски и механички алатки и заедничка хардвер. Сертификатот е

издаден од Moody International Certication Ltd, England.

ТЕХНИЧКИ ПОДАТОЦИ

параметaр единица вредност

модел -RDP-SHG20

напон V 20

Температура на излезот на млазницата ˚C 350

Температура на излезот на млазницата на

концентрацијата ˚C 550

Волумен на воздухот l/min 300

Проток на воздух l/min 500

Нивото на звучна моќност е пониско од dB(А) 70

ЕЛЕМЕНТИ ОД ДОПИС

1. Излезница на млазницата.

2. Предизвикувач - 3 режими:

0 - пиштолот е исклучен;

1 - ладен воздух - дува со ладен воздух за брзо ладење на млазницата и ладење на

грејачот;

2 - Топол воздух

3. Рачка.

4. Млазница на концентрација

5. Рефлексија на млазницата во форма на лажица

6. Површинска млазница

MK

20 www.raider.bg

1. Општи упатства за безбедна работа.

Прочитајте ги сите упатства внимателно. Неисполнување на упатствата подолу може

да резултира во електричен удар, пожар и / или сериозна повреда. Чувајте ги овие

упатства на безбедно место.

1.1. Не користете ја машината во влажна околина.

1.2. Во случај на дефект, работата за поправка мора да ја изврши само специјалист.

1.3. Бидете внимателни кога користите околу запаливи места. Не нанесувајте топол

воздух на едно место долго време.

1.4. Секогаш проверувајте дали работното место е добро проветрено. Не користете ја

машината како фен за коса.

2. Безбеден начин на работа.

2.1. Опасност од пламен!

2.2. Не допирајте ја топлата млазница (1).

2.3. Носете заштитни нараквици.

2,4. Ставете ја машината на штанд и оставете ја да се излади пред да ја зачувате.

Чувајте ја машината и нејзините резерви подалеку од децата.

2.5. Ако млазницата на машината е жешка и сакате да ги ослободите двете раце

за работа, можете да ја извадите потпирачот за држач и да ја поставите машината во

исправена положба на нејзината база.

2,6. Никогаш не насочувајте топол воздух кај луѓе или животни.

2,7. Опасност од пожар и експлозија! За време на работата, топлината може да се

пренесе на површини надвор од вид. Може да се појават запаливи и токсични гасови при

работа со пластика, бои (особено постари), лакови и слични материјали. Не користете

ја машината близу до запаливи гасови или материјали. Не чувајте ја млазницата многу

блиску до работната површина. Користете само оригинални потрошни материјали. Не

сите опишани потрошен материјал се вклучени во стандардното пакување.

4. Вклучување.

4.1. Машината мора да биде во исклучена позиција пред да се поврзе со напојувањето.

4.2. Поставете го прекинувачот за стартување (2) на положбата 2 за топол проток на

воздух.

Препорачливо е да ја чувате машината на поголемо растојание од работната површина.

Растојанието помеѓу млазницата и работното парче зависи од природата на

материјалот.

Поставете го прекинувачот за стартување (2) на позиција 1 за проток на ладен воздух.

Во „ладно дување“, алатот работи во режим на вбризгување на воздухот без греење.

Ако е потребно постојано ладење на материјалите (на пример, при изведување на работа

со заварување), мора да се земе предвид присуството на таква опција.

Студениот степен на брзо ладење на алатот го продолжува животниот век на пиштолот

со топол воздух. Можете да ги изладите површините и материјалите по третманот. Само

вентилаторот работи во студен режим; грејачот се исклучува.

5. Начин на работа и примена.

5.1. Отстранување на боја. Инсталирајте ја рамната млазница. Загрејте ја бојата додека

не биде мека и извадете ја со помош на шпатула. Не ја загревајте ја бојата премногу

долго, бидејќи тоа ќе ја обои бојата и ќе го отежне отстранувањето. Многу лепила (на

пр. Налепници) омекнуваат кога се загреваат, дозволувајќи им да се одвојат врзаните

површини и да се отстрани теченото лепило.

5.2. Отстранување на боја од прозорци. Чашата е кршлива. Секогаш користете ја

млазницата предвидена за стакло. Од вертикалните површини, бојата може да се

отстрани со шпатула или мека жица четка.

5.3. Формирање на пластични цевки. Инсталирајте ја млазницата на рефлекторот. За

да избегнете оштетување на цевките, пополнете со песок од двете страни и приклучете

ги двата краја. Загревајте го барелот постепено додека го придвижувате пиштолот од крај

до крај.

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

Lucrări înrudite

-

RAIDER Pro RDP-HG21 Manual de utilizare

-

RAIDER Pro RDP-SWL20 Manual de utilizare

-

RAIDER Pro RDP-SRW20 Manual de utilizare

-

RAIDER Pro RDP-SPC20 Manual de utilizare

-

RAIDER Pro RDP-SDWCH20 Manual de utilizare

-

RAIDER Pro RDP-SBES20 Manual de utilizare

-

RAIDER Pro RDP-SCDI20S Manual de utilizare

-

RAIDER Pro RDP-SCDI20S Manual de utilizare

-

RAIDER Pro R20 Rapid Charger 8A Manual de utilizare

-

RAIDER Pro RDP-SCIW20 Manual de utilizare

Alte documente

-

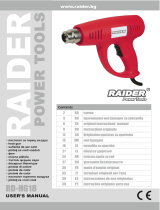

Raider Power Tools RD-HG18 Manual de utilizare

Raider Power Tools RD-HG18 Manual de utilizare

-

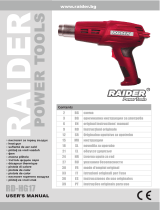

Raider Power Tools RD-HG17 Manual de utilizare

Raider Power Tools RD-HG17 Manual de utilizare

-

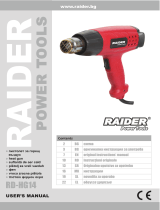

Raider Power Tools RD-HG14 Manual de utilizare

Raider Power Tools RD-HG14 Manual de utilizare

-

Raider Power Tools RD-HG23 Manual de utilizare

Raider Power Tools RD-HG23 Manual de utilizare

-

Raider Garden Tools RDP-SBGP20 Manual de utilizare

-

Raider Garden Tools PRO RDP-SBBC20 Manual de utilizare

-

Raider Garden Tools RDP-SEBV20 Manual de utilizare

-

Raider Garden Tools RDP-SBKMD20 Manual de utilizare

-

Raider Power Tools RD-SG04 Manual de utilizare

Raider Power Tools RD-SG04 Manual de utilizare

-

Raider Garden Tools RD-CBL04 Manual de utilizare