English (GB)

14

7.5.3 Phase insulation, MG 71 and 80

MG motors, frame sizes 71 and 80, do not have phase insulation

as standard. The motors are not suitable for frequency converter

operation as they are not protected against the voltage peaks

caused by the frequency converter operation. Only motors with a

rated voltage equal to or above 460 V have phase insulation.

We recommend that you protect all other motors against voltage

peaks higher than 1200 V by 2000 V/μsec.

You can eliminate the above disturbances, i.e. both increased

acoustic noise and detrimental voltage peaks by fitting an LC filter

between the frequency converter and the motor.

For further information, contact the frequency converter or motor

supplier.

7.5.4 Other motor makes than those supplied by Grundfos

Contact Grundfos or the motor manufacturer.

8. Startup

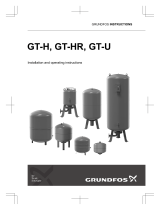

Fig. 21 Vent valve, standard and an optional solution with

hose connection

Follow the instructions on page 351.

CR, CRI, CRN 1s to 5

For these pumps, we advise you to open the bypass valve during

startup. See fig. 22 for bypass valve location. The bypass valve

connects the inlet and outlet sides of the pump, thus making the

filling procedure easier. Close the bypass valve again when the

operation is stable.

When pumping liquids containing air, we advise you to leave the

bypass valve open if the operating pressure is lower than 6 bar.

Close the bypass valve if the operating pressure constantly

exceeds 6 bar. Otherwise the material at the opening will be worn

because of the high liquid velocity.

8.1 Shaft seal run-in

The seal faces are lubricated by the pumped liquid, meaning that

there may be a certain amount of leakage from the shaft seal.

When you start the pump for the first time, or when you install a

new shaft seal, a certain run-in period is required before the

leakage is reduced to an acceptable level. The time required for

this depends on the operating conditions, i.e. every time the

operating conditions change, a new run-in period will be started.

Under normal conditions, the leaking liquid will evaporate. As a

result, no leakage will be detected.

9. Maintenance

Pump bearings and shaft seal are maintenance-free.

Motor bearings

Motors not fitted with grease nipples are maintenance-free.

Motors fitted with grease nipples must be lubricated with a high-

temperature, lithium-based grease. See the instructions on the

fan cover.

In the case of seasonal operation where the motor is idle for more

than 6 months of the year, we recommend that you grease the

motor when you take the pump out of operation.

Depending on the ambient temperature, replace or lubricate the

motor bearings according to the table below. The table applies to

2-pole motors. The number of operating hours stated for bearing

replacement are guidelines only.

Intervals for 4-pole motors are twice as long as those for 2-pole

motors.

If the ambient temperature is lower than 40 °C, then replace or

lubricate the bearings at the intervals mentioned under 40 °C.

Frequency converter operation of MG motors without

phase insulation will cause damage to the motor.

Do not start the pump until it has been filled with

liquid and vented. If the pump runs dry, the pump

bearings and the shaft seal may be damaged.

TM05 1160 0611 - TM05 8098 1913

Warning

Pay attention to the direction of the vent hole and

make sure that the escaping water does not cause

injury to persons or damage to the motor or other

components.

In hot-water installations, pay special attention to the

risk of injury caused by scalding hot water.

Warning

Make sure that a leakage does not cause injury to

persons or damage to the equipment.

Warning

Before starting work on the pump, make sure that all

power supplies to the pump have been switched off

and that they cannot be accidentally switched on.

Motor size

[kW]

Bearing replacement interval [operating hours]

40 °C 45 °C 50 °C 55 °C 60 °C

0.37 - 0.75 18000----

1.1 - 7.5 20000 15500 12500 10000 7500

Motor size

[kW]

Lubrication interval [operating hours]

40 °C 45 °C 50 °C 55 °C 60 °C

11 - 18.5 4500 3400 2500 1700 1100

22 4000 3100 2300 1500 1000

30-55 4000 3000 2000 1500 -

75 2000 1500 1000 500 -