Mark GSX 90 Technical Manual

- Categorie

- Seminee

- Tip

- Technical Manual

Acest manual este potrivit și pentru

Technical manual

Technisches Handbuch

Livret technique

Technisch boek

Instrukcja techniczna

Manual tehnic

Teknisk vejledning

EN

DE

FR

NL

PL

RO

MARK GSX

0660150_R12

DK

3

Read this document before

installing the heater

If the manual refers to an image or table, a number will be shown between square brackets, for

example [3]. The number refers to images and tables at the back of the manual with the stated

number.

1.0 General

1.1 Application

The GSX appliance is designed for heating industrial and other non-domestic areas. The appliances

must be installed in a xed installation, preferably above the work oor, taking into account

minimum distances. Appliance type GSX is solely suitable for the free and direct intake of the air to

be heated and the free discharge of heated air into the room.

If areas are to be heated in which corrosive vapours are present (chlorinated hydrocarbons in

particular), which are either produced directly in the area, or which may be drawn in from the

outside by the heater via a duct or an open connection, wall air heaters cannot be used because of

the risk of corrosion to the heat exchanger.

Subject to change

The manufacturer is committed to constantly improving its products and reserves the right to make

changes in the specications without prior notice. The technical details are considered correct but

do not form the basis for a contract or warranty. All orders are accepted according to the standard

terms of our general sales and delivery conditions (available upon request). The information in this

document is subject to change without notice. The most recent version of this manual is always

available at www.markclimate.com/downloads.

1.2 Type indication

GSX

G Gas

S Axial fan

X Not condensating

Warning

Incorrect installation, adjustment, alteration, repair or maintenance work may lead to material

damage or injury. All work must be carried out by certied, qualied professionals. If the

appliance is not positioned in accordance with the instructions, the warranty shall be rendered

void. This appliance is not intended for use by children or persons with a physical, sensory or

mental handicap, or who lack the required experience or expertise, unless they are supervised

or have been instructed in the use of the appliance by somebody who is responsible for their

safety. Children must be supervised to ensure that they do not play with the appliance.

EN

All the types of appliance are listed in table [3]. The various types are shown in the rows, and

technical information relating to the appliances is shown in the columns. See the key below.

Key to table [3]

A Nominal load (upper value)

B Nominal load (lower value)

C Nominal power

D Gas consumption for a specied gas type (15°) max/min

D1 CO

2

/O

2

for a specied gas type: max. load %

D2 CO

2

/O

2

for a specied gas type: min. load %

D3 Gas pre-pressure for a specied gas type

E Flue gas temperature (+/- 10°C)

G Burner fan start-max.-min.

H Diameter of the ue gas duct/air supply duct

I Electrical supply

J Electrical power

K Appliance fuse rating

L Protection class

M Air displacement (20°C)

N Air temperature rise

O Throw

P Ambient temperature min. /max.

Q Fan diameter(s)

R Fan speed

S Weight

T Flue gas mass

U Available ue pressure

V Gas connection

Information for Belgium

AA Nominal load (lower value) H gas / L gas

BB Power H gas / L gas

1.3 General warnings

Incorrect installation, adjustment, alteration, maintenance or repair may lead to material or

environmental damage and/or injuries. The appliance may therefore only be installed, adapted

or converted by a skilled and qualied installer, taking into account national and international

regulations. Faulty installation, adjustment, alteration, maintenance activity or repair shall render the

warranty void.

Appliance

When installing wall air heaters, you must comply with the relevant national and, if applicable,

regional and local regulations (e.g. gas company regulations, building regulations etc.). The wall

air heater may be installed only in an area and position suitable for the purpose, see Chapter 2

Installation. In Belgium, the wall air heater must be installed in accordance with Belgian standard

NBN D51-003.

Gas supply and connection

Before installation, check that the local distribution conditions, gas type and pressure and the

current adjustment of the appliance all match. An approved gas stop cock must be tted to the inner

pipeline.

4

5

Flue gas route

Combustion air supply pipelines and combustion gas exhaust ducts should have as few bends as

possible; in general, ow resistance should be kept to a minimum and in all cases, the diameter

should be constant along the entire length. The exhaust duct may not rest on the heater, but should

be suspended efciently! Follow the bracket instructions in chapter 10. If the ue gas exhaust duct

passes along or through combustible walls or oors, the duct must be sufciently far away from the

combustible material to prevent re.

1.4 Think of your safety

If you smell gas, you must not under any circumstances:

– Ignite an appliance

– Touch electrical switches or telephone from the area in question

Take the following action:

– Switch off the gas and electricity

– Activate the operational emergency plan

– Evacuate the building if necessary

2.0 Installation

2.1 Positioning the appliance

After unpacking, check the appliance for damage. Check that the information relating to the type/

model and the electrical voltage is correct. Install the appliance and any accessories to a sufciently

solid structure [2], taking into account the minimum free space required [1].

For GSX you should use the four M10-sized suspension points [21].

2.2 Positioningtheuegasexhaustsystemandairsupply

The device only has the CE approval in combination with its ue gas system. The ue gas system

includes: single ue set vertical or horizontal, extension pipes and elbows. Table [4] indicates

which parts can be used per appliance type. The ue gas system must be installed according to the

instructions attached.

If a ue gas set is to be installed sideways to or through a ammable oor or wall, then there must

be a minimum air gap of 25 mm around the ue gas sets. This to prevent re and / or scorch hazard.

The mentioned ue gas products are made of aluminum or stainless steel.

The combustion air inlet pipes may consist of the same materials as specied for the ue gas

discharge, but may also consist of materials mentioned in the table on pages 6-8. Other materials are

not allowed.

The maximum lenght of the ue gas system and combustion air inlet pipes is 6 meters and with 1x2

bends of 90°. Contact the manufacturer when exceeding the maximum discharge lenght.

The roof and wall pass-throughs supplied by the manufacturer are identied by the following item

numbers:

Appliance type Roof pass-through C33 Wall pass-through C13

GSX 20/35

GSX 55/75/90

59 90 556

59 90 560

59 90 579

59 90 583

EN

6

The extension pipes and bends of the gas ue exhaust system must satisfy the following

requirements:

Appliance type Minimum diameter

GSX 20/35

GSX 55/75/90

80 mm

100 mm

Type Flue gas exhaust Accessories Installation

remarks

Appliance

type

Ø Article

code

Ø Artikel-

nr.

B53 Single ue set vertical ALU Extension

pipe L=500

The ue gas

exhaust pipes

must be made

of aluminum or

stainless steel.

The combustion

air inlet pipes

can be made of

stainless steel,

aluminum or

polyethylene.

The maximum

length of the ue

gas system is:

- GSX 20:

5 meter pipe and

2 bends of 90°.

- GSX 35-90: 6

meter pipe and 2

bends of 90°.

20/35 5990556 80 5990727

55/75/90 5990560 100 5990728

ALU Extension

pipe L=1000

80 5990732

100 5990736

ALU Bend 45°

80 5990734

100 5990738

ALU Bend 90°

80 5990733

100 5990737

Stainless steel

Extension pipe

L=500

80 5990201

100 5990211

Stainless steel

Extension pipe

L=1000

80 5990202

100 5990212

Stainless steel

Bend 45°

80 5990204

100 5990214

Stainless steel

Bend 90°

80 5990203

100 5990213

Air inlet mesh

80 3002532

100 3002533

7

C13 Single ue set horizontal

20/35 80/125 5990579

55/75/90 100/150 5990583

Flue gas

exhaust

The ue gas

exhaust pipes

must be made

of aluminum or

stainless steel.

The combustion

air inlet pipes

can be made of

stainless steel,

aluminum or

polyethylene.

The maximum

length of the ue

system is:

- GSX 20:

2x5 meter pipe

and 2x2 bends

90°.

- GSX 35-90:

2x6 meter pipe

and 2x2 bends

90°.

ALU Extension

pipe L=500

80 5990727

100 5990728

ALU Extension

pipe L=1000

80 5990732

100 5990736

ALU Bend 45°

80 5990734

100 5990738

ALU Bend 90°

80 5990733

100 5990737

Stainless steel

Extension pipe

L=500

80 5990201

100 5990211

130 5990221

Stainless steel

Extension pipe

L=1000

C33 Single ue set vertical 80 5990202

20/35 80/125 5990556 100 5990212

55/75/90 100/150 5990560 130 5990222

Stainless steel

Bend 45°

80 5990204

100 5990214

130 5990224

Stainless steel

Bend 90°

80 5990203

100 5990213

130 5990223

EN

8

C53

Max. 3 m

Single ue set vertical Combustionair C53: The

condensate must

be discharged

efciently,

according to

the applicable

national

regulations.

20/35 80/125 5990556 Stainless steel

or ALU

Extension pipe

(see above)

55/75/90 100/150 5990560 OR

In combination with

single ue set horizontal

Polyethylene

Extension pipe

L=500

20/35 5990511 80 5989205

55/75/90 5990512 100 5989206

OR Polyethylene

Extension pipe

L=1000

20/35 0703100 80 5989210

55/75/90 0703101 100 5989211

Polyethylene

Bend 45°

80 5989224

100 5989233

Polyethylene

Bend 90°

80 5989225

100 5989236

C43 C43: Minimum

internal area of a

round common

drain pipe AV,

see table [5]

Applicable only

if the combined

ue gas system

has sufcient

natural draft: the

unit does not

have an internal

non-return valve.

Condensate is

not allowed to

ow back from

the ue system

into the unit.

C83 Single ue set horizontal

20/35 5990511

55/75/90 5990512

9

2.3 Gas connection

The installation of the gas pipeline and gas tap must comply with the relevant local and/or national

regulations. The gas tap must be positioned within reach of the appliance [3]. If the connection line is

subject to pressures above 60mbar, this gas tap must be closed. If there is any possibility of the presence

of dirt in the gas, use a gas lter. Always blow through the gas pipe in compliance with the regulations

prior to operating the appliance. If the appliance needs to be converted to a different type of gas than that

indicated on the type plate, the supplier of the appliance must be contacted. The supplier can advise you

which parts must be replaced in order to ensure correct operation of the appliance with the desired type

of gas. Conversion to a different type of gas is not permitted in Belgium.

2.4 Electrical connection

Installation must comply with the relevant local and/or national regulations. Ensure that there is a correct

connection group with a mains fuse. The electrical diagram is displayed on the appliance. A basic diagram

for the GSX appliance can be found in chapter 8 and 9 Electrical diagram.

PLEASE NOTE:

– The appliance must be adequately earthed. The appliance must be tted with an isolator switch

which interrupts phase and zero (not earth).

– The isolator switch must be accessible at all times.

– Never, under any circumstances, allow the supply to the appliance to be interrupted by other

switches. This could result in the appliance overheating.

– The unit is phase sensitive.

3.0 Controls

3.1 Roomthermostatandresetbutton

The room thermostat must be located at a height of approx. 1.5m and not directly within the ow of

warm air. Connect the room thermostat using a shielded data cable in accordance with the wiring diagram

supplied for the appliance. Refer also to the technical information handbook supplied with the room

thermostat. Incorrect connection will render the manufacturer’s warranty void.

PLEASE NOTE:

– The maximum lengths and diameters are specied in the table [26].

– Earth the cable shielding to the appliance.

– For connecting multiple appliances, see [25] + [26].

3.2 Choiceofbuscable

Selection of the correct type of bus cable is based on the specic model for the country concerned. When

selecting the cable, the values noted in the technical details must be complied with. Bus cables of the

appropriate specications, which are offered in countries with an EIB market, are:

– YCYM Fixed system

EIB specication Dry, damp, wet rooms

In the open air (no direct exposure to sunlight)

Face-t, ush-t, in conduits

– J-Y(st)Y Fixed system

EIB specication Only in interior spaces

Face-t, in conduits

– JH(st)H Halogen-free conduits, remote system

– A-2Y(L)2Y or A-2YF(L)2Y Telephone ground cable, system in the outside area

EN

10

4.0 Start-up/shutdown

4.1 General

Before being packed, each appliance is fully tested for safety and correct operation. Among other

checks, the gas pressure and CO

2

are set. You must however always check the gas pre-pressure.

Never turn the adjusment screws without good cause. Do not forget to instruct the user on the

proper use and operation of the appliance and peripherals.

4.2 Checks

– Switch off the electricity supply at the main switch.

– Set the room thermostat to the minimum temperature.

– Open the gas stop cock, then carefully purge the gas pipes of air and check for leaks. Under no

circumstances use a naked ame! [27]

– Close the gas stop cock.

– In the case of the GSX, check whether the vanes in the air discharge port are set to the open

position (open to a min. of 45º).

– Switch on the electrical supply at the main switch and set the room thermostat to maximum

temperature. After the purge time has elapsed, the automatic ignition control will generate an

electric spark and the safety valve on the gas control unit will open. Because the gas stop clock is

closed, no ame will appear. The automatic ignition control will lock out after 4 attempts at

ignition, each lasting about 5 seconds. After waiting for approximately 30 seconds, the automatic

controller can be reset and the same cycle can be repeated.

– Open the gas stop cock, the appliance will now start up.

– Check the ame pattern at the main burner (clearly dened inner core, even combustion).

– In the case of appliances with an external fan, check that the maximum temperature increase of

30K is not exceeded.

4.3 Checkthattheroomthermostatisfunctioningcorrectly

If the setting is lower than the ambient temperature, the burner will extinguish. At a setting higher

than the ambient temperature, the burner should ignite.

4.4 Check the pre-pressure

The gas pre-pressure must be measured at the gas unit when the appliance is in operation. The pre-

pressure is indicated on the appliance’s type plate. To check, the volume of gas consumed [3] can be

measured via the gas meter (temporarily switch off all other appliances that consume gas).

4.5 Check appliance operation.

Finally, check that the operation of the appliance cannot be inuenced by other appliances close to

it, localised air ows or corrosive or explosive vapours, etc.

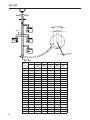

4.6 Set the gas control unit [6]

Before being packed, each appliance is fully tested for safety and correct operation. The correct

combustion values are set during this procedure. If checks indicate that the CO

2

value is different

from that in table [3], adjustments may be made (difference of more than 0.2%). Never adjust set

screws without the correct measuring equipment.

11

Legend [6]

1 Measuring point for gas pre-pressure

2 Measuring point for offset

3 Offset adjustment screw

4 Throttle adjustment screw

Step 1

Set the appliance to run at full operational load by pressing and holding the reset button of the unit

for at least 5 seconds. The fault lamp in the reset button ashes at a high frequency. If the appliance

will not re up, you can try sealing the air opening in the gas mixer during ignition using your thumb

and index nger. This makes the mixture richer and easier to ignite. Check the CO

2

when the

appliance is operating at high output. If the CO

2

is too high, turn the throttle adjuster to the right

(less gas). If the CO

2

is too low, turn the screw to the left (more gas). The correct CO

2

value is

shown in table [3] (D1).

Step 2

Set the appliance to minimum load by shortly pressing the reset button of the unit. The fault lamp

in the reset button ashes at a low frequency. Check the CO

2

against the value in table [3] (D2). If

different, correct by turning the offset adjuster under the cap. To the left for lower CO

2

, to the right

for higher CO

2

.

After setting the gas control unit press the reset button again (the light goes out).

4.7 Shutting down the heater

For short periods of time:

– Set the room thermostat to the minimum temperature.

– Do not switch off the electricity supply at the main switch as this may damage the maximum

temperature and safety thermostat.

For longer periods of time:

– Set the room thermostat to the minimum temperature.

– After ± 5 minutes, the electrical power may be switched off.

5.0 Maintenance

5.1 General

The appliance must be subjected to maintenance at least once a year, more often if necessary. If

applicable, ask a qualied installer for maintenance advice. Maintenance may only be carried out by

qualied maintenance technicians. When carrying out maintenance, the appliance must have been

shut down for an extended period. Make sure that you comply with all safety rules.

5.2 Cleaning

All gas-red appliances require periodical maintenance. This maintenance work must be performed

by qualied maintenance technicians.

– Before starting maintenance work, the gas and electrical supplies must be shut off. See also

paragraph 4.7

– Check all gaskets and replace if required.

– The gas transport section is located on the side of the appliance in the electrical compartment.

The gas transport section can be removed from the appliance as a single assembly. To do so, six

M6 nuts must be removed and the electrical wiring disconnected.

EN

12

– Removal of the gas transport section provides access to the burner and the ignition/ionisation

electrode. It is recommended to replace the ignition/ionisation electrode yearly during regular

maintenance.

– Check the burner surface for irregularities. Never use a steel brush!

– Clean the gas mixer using a soft brush. Make sure that no dust gets into the burner and the gas

suction tube. Ret the gas transport section, reconnect the wiring and the gas and electrical

supplies. [27]

6.0 Description of parts

The parts are:

– Fan [7]

– Combustion air fan [8]

– Ignition set [9]

– Burner [11]

– Gas control unit [12]

– Ambient temperature sensor [13]

– Outlet temperature sensor / max [14]

– Gasket set [15]

– Microprocessor [16]

– Gas mixer [17]

7.0 Fault codes

Code Error Description

01 Ignition failure Ignition has failed (three attempts at ignition).

02 Gas valve relay/T max. Maximum thermostat is open

03 Gas valve

Gas valve faulty / Wire connecting the gas valve to the

burner control box is open-circuit or has been incorrectly

connected.

10 Sensor diff too high

Temperature difference between both outlet temperature

sensors is too high.

25 T max. Maximum thermostat is open

31 Too many attempts to restart Flame goes out (3x) when the device is in operation.

42 Choke relay broken Relay of the choke valve is broken

43 Combustion air fan failure

The current speed of the combustion air fan deviates too

much

65 Phase and zero back to front Phase and zero not connected correctly

72 Air out sensor open Outlet temperature sensor interrupted

73 Unit temp sensor open Ambient temperature sensor interrupted

78 Air out safety open Outlet temperature sensor interrupted

80 Air out shorted Outlet temperature sensor has short circuited

81 Unit temp shorted Ambient temperature sensor has short circuited

86 Air out safety shorted Outlet temperature sensor has short circuited

When a different error code displayed on the thermostat appears, press the Reset button. If the fault

returns, please contact the vendor of the device.

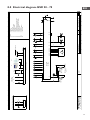

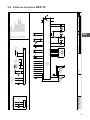

8.0 Electrical diagram GSX 20 - 75

EN

13

14

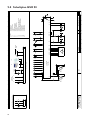

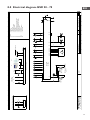

9.0 Electrical diagram GSX 90

15

EN

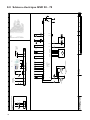

10.0 Bracket instructions

[20] Basic instructions

Single-wall steel ue system

These basic requirements are only applicable to connecting pipes with the following

characteristics:

• Connection to a heater with built-in ventilator.

• Connection in the installation area of the appliance and in sight.

• Single-walled, rigid aluminium or stainless steel pipes with CE certication (cf EN

1856-1/2, P1, W).

• Maximum ue gas temperature of 160ºC.

• Diameters from Ø80 to Ø130 mm.

Caution! This checklist includes some basic instructions. For further

instructions for this unit paragraph 2.2.

Checklist

General

We recommend using the brackets of manufacturer Cox Geelen.

Do not combine components of various materials or nished products for the

connecting pipe, except where the manufacturer of the system allows this. Exception

to this rule: components tested according to Gastec Qa KE83-3 (thick-walled

aluminium) and 5 (stainless steel).

The minimum insertion length of sleeves and spigot ends is 40mm.

Mount tension free.

Create a slope 3 degrees (so 50mm per meter) to the unit for a proper drainage of

the condensate.

Connecting and bracing

Brace every corner to or close to the sleeve. Exception when connecting to the unit:

- If the connecting pipe is shorter than 0.25m before and after the rst ben, the

bracket at the rst bend can be omitted.

- Place the rst bracket on a maximum of 0.5m pipe length from the unit.

Horizontal and non-vertical pipes

- Maximum bracket distance of 1m.

- Divide lengths between brackets evenly.

Vertical pipes

- Maximum bracket distance of 2m.

- Divide lengths between brackets evenly.

Gaskets and seals

Avoid damaging of the sealing rings by cutting of in an angle and deburring.

When using tension-proof connections follow the instructions of the manufacturer.

Do not screw or park connections.

It is not allowed to seal foam or paste (for example PUR, silicone, etc.).

If necessary lubricate sealing rings exclusively with max. 1% soap solution or water.

Caution! Do not use grease, Vaseline, petroleum jelly or oil.

Air supply system

These basic instructions are only applicable to air supply pipes with the following

characteristics:

• Connection to a closed heater with built-in fan.

• Connection in the installation area of the appliance and in sight.

• Aluminium, stainless steel or plastic air supply pipes.

• Diameter air supply pipe of Ø80 to Ø130 mm.

Caution! This checklist includes some basic instructions. For further

instructions for this unit paragraph 2.2.

Checklist

General

Do not combine components of various materials or nished products for the

connecting pipe.

The minimum insertion length of sleeves and spigot ends is 40mm.

When using plastic air supply pipes make sure that the distance to the ue pipe is at

least 35mm.

Mount tension free.

Connecting and bracing

Place the rst bracket on a maximum of 0.5m pipe length from the unit.

Horizontal and non-vertical pipes

- Maximum bracket distance of 1m.

- Divide lengths between brackets evenly.

Vertical pipes

- Maxium bracket distance of 2m.

- Divide lengths between brackets evenly.

Gaskets and seals

Avoid damaging of the sealing rings by cutting of in an angle and deburring.

Seals of metal air supply pipes may be bolted or parked. This is not allowed for plastic

air supply pipes.

Guarantee the gas-thightness by using components that are provided with a seal.

If necessary lubricate sealing rings exclusively with max. 1% soap solution or water.

Caution! Do not use grease, Vaseline, petroleum jelly or oil.

17

DE

Lesen Sie dieses Dokument sorgfältig

durch, bevor Sie das Gerät installieren

Wenn in der Anleitung auf eine Abbildung oder Tabelle verwiesen wird, wird eine Zahl in eckigen

Klammern angegeben, beispielsweise [3]. Die Zahl verweist auf die Abbildungen und Tabellen mit

der entsprechenden Nummer am Ende der Anleitung.

1.0 Allgemeines

1.1 Einsatzbereich

Der GSX ist für die Beheizung von industriellen und anderen Nicht -Wohngebäuden konzipiert.

Die Geräte müssen in einer festen Anordnung, vorzugsweise oberhalb der Arbeitsäche, und unter

Berücksichtigung von Mindestabständen installiert werden. Das Gerät GSX eignet sich ausschließlich

zum freien und direkten Ansaugen der zu erwärmenden Luft und zum freien ausblasen der

erwärmten Luft in den Raum.

Zum Heizen von Räumen, in denen korrosive Dämpfe vorhanden sind (insbesondere chlorierte

Kohlenwasserstoffe), die entweder direkt aus dem Raum oder über einen Anschluss oder eine

offene Verbindung von außen durch den Warmlufterzeuger angesaugt werden können, können diese

aufgrund der Korrosionsgefahr für den Wärmetauscher nicht eingesetzt werden.

Änderungen vorbehalten

Der Hersteller strebt eine kontinuierliche Verbesserung der Produkte an und behält sich das

Recht vor, ohne vorherige Mitteilung Änderungen an den technischen Daten vorzunehmen. Die

technischen Angaben werden als korrekt angenommen, bilden aber keine Grundlage für einen

Vertrag oder Gewährleistungsansprüche. Alle Bestellungen werden gemäß den Standardkonditionen

in unseren AGB‘s (auf Anfrage erhältlich) angenommen. Die Informationen in diesem Dokumente

können sich ohne vorherige Ankündigung ändern. Die neuste Version dieses Handbuches nden Sie

immer auf unserer Interseite unter www.mark.de/downloads.

1.2 Typenkennzeichnung

GSX

G Gas

S Axialventilator

X nicht kondensierend

Warnhinweis

Fehlerhaft durchgeführte Installationen, Einstellungen, Änderungen, Reparaturen oder

Wartungsmaßnahmen können zu Sachschäden und Verletzungen führen. Alle Arbeiten

müssen von geprüften, qualizierten Fachleuten durchgeführt werden. Falls das Gerät nicht

vorschriftsgemäß aufgestellt wird, erlischt die Garantie.

Dieses Gerät ist nicht für den Gebrauch durch Personen (einschließlich Kindern) mit

verminderter körperlicher, Sinnes- oder geistiger Leistungsfähigkeit oder mangelnder

Erfahrung und mangelnden Kenntnissen bestimmt, sofern sie nicht unter Aufsicht stehen

oder durch eine Person, die für ihre Sicherheit verantwortlich ist, im Gebrauch des Geräts

angeleitet werden. Kinder müssen vom Gerät ferngehalten werden.

18

Alle Gerätetypen sind in Tabelle [3] aufgeführt. In den Zeilen sind die verschiedenen Typen

aufgeführt, in den Spalten die technischen Angaben zu den Geräten. Siehe die folgende Legende.

Legende zu Tabelle [3] (Seite 92)

A Nennbelastung (oberer Wert/Brennwert)

B Nennbelastung (unterer Wert/Heizwert)

C Nennleistung

D Gasverbrauch bei bestimmten Gasarten (15°C) max./min.

G25 - L-Gas

G20 - H-Gas

D1 CO

2

/O

2

bei bestimmten Gasarten: max. Belastung %

D2 CO

2

/O

2

bei bestimmten Gasarten: min. Belastung %

D3 Gasießdruck bei bestimmten Gasarten

E Abgastemperatur (+/- 10°C)

G Drehzahl Brennerventilator Start-max-min

H Durchmesser Abgassystem/Luftzufuhr

I Einspeisung

J Elektrische Leistung

K Absicherung

L Schutzklasse

M Luftleistung (20 °C)

N Lufttemperaturerhöhung

O Wurfweite

P Umgebungstemperatur min. /max

Q Lüfterdurchmesser

R Lüfterdrehzahl

S Gewicht

T Abgasmassenstrom

U Förderdruck

V Gasanschluss

Informationen für Belgien

AA Nennbelastung (unterer Wert/Heizwert) H Gas / L Gas

BB Leistung H Gas / L Gas

1.3 AllgemeineWarnhinweise

Eine unsachgemäß ausgeführte Installation, Feinabstimmung, Änderung, Inspektion oder

Instandsetzung kann zu Materialschäden, Umweltschäden und/oder Verletzungen führen. Lassen

Sie das Gerät daher nur von fachkundigen und qualizierten Installateuren unter Berücksichtigung

der nationalen und internationalen Vorschriften installieren, anpassen oder umbauen. Im Falle

einer unsachgemäßen Installation, Einstellung, Änderung, Wartung oder Instandsetzung erlischt die

Gewährleistung.

Gerät

Bei der Installation von wandmontierten Lufterhitzern sind die geltenden nationalen und ggf.

regionalen und lokalen Vorschriften (z.B. Vorschriften des Gasunternehmens, Bauverordnungen,

usw.) zu beachten. Die Installation des Warmlufterzeuger darf ausschließlich in hierfür geeigneten

Räumen und an einem hierfür geeigneten Ort erfolgen; siehe Kapitel 2, Installation. In Belgien ist der

Lufterhitzer gemäß der belgischen Norm NBN D51-003:2010+A1:2014 zu installieren.

19

DE

Gaszufuhr und Gasanschluss

Überprüfen Sie vor der Installation, ob die lokalen Versorgungsbedingungen, Gasart und -druck und

die aktuelle Einstellung des Geräts miteinander übereinstimmen. An der Innenleitung ist ein geprüfter

Gasabsperrhahn anzubringen.

Abgasstrecke

Zuluftleitungen und Abgasleitungen sollten möglichst wenig Krümmungen aufweisen; grundsätzlich

muss der Widerstand auf ein Minimum beschränkt und in jedem Fall derselbe Durchmesser über die

gesamte Strecke eingehalten werden. Die Ableitung darf nicht auf dem Warmlufterzeuger abgestützt

werden, sondern muss in zweckmäßiger Weise aufgehängt werden (beachten Sie bitte die Anweisung

aus Kapital 10.) Wenn die Abgasableitung durch brennbare Wände oder Böden oder an ihnen

entlang geführt wird, muss die Leitung zur Vermeidung von Bränden einen ausreichenden Abstand

haben.

1.4 Denken Sie an Ihre Sicherheit

Wenn Sie Gasgeruch wahrnehmen, ist es ausdrücklich verboten:

– ein Gerät zu zünden

– elektrische Schalter zu berühren oder in demselben Raum zu telefonieren

Ergreifen Sie die folgenden Maßnahmen:

– Gaszufuhr und Strom abschalten

– Betriebsnotfallplan aktivieren

– Ggf. das Gebäude evakuieren

2.0 Installation

2.1 Aufstellung des Geräts

Überprüfen Sie das Gerät nach dem Auspacken auf Beschädigung. Überprüfen Sie die Richtigkeit

des gelieferten Typs/Models sowie die elektrische Spannung. Montieren Sie das Gerät und etwaige

Zubehörteile an eine ausreichend stabile Konstruktion [2] unter Berücksichtigung der erforderlichen

Mindestabstände [1].

Verwenden Sie für den GSX (Gerät mit Axialventilator) die vier M10 Aufhängepunkte [21].

2.2 AnbringenderAbgasableitungundderLuftzufuhr

Das Gerät hat nur eine CE-Zulassung in Kombination mit dem von MARK gelieferten Abgassystem,

mit Ausnahme des Abgassystems vom Typ C43/C83.

Das Abgassystem umfasst: Dach- und Wanddurchführung, Verlängerungen und Bögen. Aus der

Tabelle [4] können Sie entnehmen, welche Anbauteile für welchen Gerätetyp verwendet werden

können. Das Abgassystem muss entsprechend der beiliegenden Anleitung installiert werden.

Zur Vermeidung von Bränden, müssen Abgasleitungen entlang oder durch brennbare Wände oder

Böden mit einem Mindestabstand von 25 mm verlegt werden.

Die genannten Produkte zur Rauchgasabfuhr bestehen aus Aluminium und Edelstahl.

Die Zuluftleitungen können aus gleichem Material bestehen, wenn sie für Abgas zugelassen sind,

oder aus Materialien, die in der Tabelle auf Seite 20-23 aufgeführt sind. Andere Materialien sind nicht

zugelassen.

Die max. Länge des Abgasrohres und der Verbrennungsluftzufuhrleitung beträgt 6m, zusätzlich 1x2

Bögen von 90˚. Kontaktieren Sie den Hersteller, wenn Sie die maximale Länge überschreiten.

Anordnung und Anzahl der Revisionsöffnungen nach DIN 18160.

20

Die vom Hersteller mitgelieferten Dach- und Wanddurchführungen haben folgende Artikelnummer:

Gerätetyp Dachdurchführung C33 Wanddurchführung C13

GSX 20/35

GSX 55/75/90

59 90 556

59 90 560

59 90 579

59 90 583

Die Verlängerungsrohre und -bögen des Abgassystems müssen die folgenden Anforderungen erfüllen:

Gerätetyp Mindestdurchmesser

GSX 20/35

GSX 55/75/90

80 mm

100 mm

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

Mark GSX 90 Technical Manual

- Categorie

- Seminee

- Tip

- Technical Manual

- Acest manual este potrivit și pentru

în alte limbi

- français: Mark GSX 90

- English: Mark GSX 90

- polski: Mark GSX 90

- Deutsch: Mark GSX 90

- dansk: Mark GSX 90

- Nederlands: Mark GSX 90

Lucrări înrudite

Alte documente

-

Maestro MR 920 Manualul proprietarului

-

Maico AWB 100 TC Mounting And Operating Instructions

-

Riello Caldariello Condens 25 KIS Manual de utilizare

-

Riello Caldariello 24 KIS C Installer And User Manual

-

Ferroli SKY ECO F 17 Instructions For Use, Installation And Maintenance

-

Ferroli BLUEHELIX TECH C Instructions For Use, Installation And Maintenance

-

De Dietrich MS 24 BIC FF Manualul proprietarului

De Dietrich MS 24 BIC FF Manualul proprietarului

-

Ferroli Diva F24 Manual de utilizare

-

Schneider Electric MTN6003-0013 KNX Flush Mounted Universal Dimming Acutator 1g Manual de utilizare

-

iGuzzini MH96 Ghid de instalare