Ferm HDM1024 Manual de utilizare

- Categorie

- Unelte electrice

- Tip

- Manual de utilizare

EN

Original instructions

03

Art.no. HDM1024

ROTORY HAMMER DRILL

EBH-850KN

1102-24

2

9

11

Front switch lever Back switch lever

D1

D2

D3

2

3

4

6

10

11

8

7

9

1

12

5

Fig. C Fig. D

Fig. B

Fig. A

FIG.

EN

3

ROTARY HAMMER DRILL

Thank you for buying this Ferm product.

By doing so you now have an excellent product,

delivered by one of European leading suppliers.

All products delivered to you by Ferm are

manufactured according to the highest standards

of performance and safety. As part of our

philosophy we also provide an excellent customer

service, backed by our comprehensive Warranty.

We hope you will enjoy using this product for

many years to come.

The numbers in the following text correspond

with the pictures at page 2.

Read this manual carefully, before using the

machine. Ensure that you know how the

machine works, and how it should be

operated. Maintain the machine in

accordance with the instructions, and make

certain that the machine functions correctly.

Store this manual and other enclosed

documentation with the machine.

Intended use

The EBH-850KN is intended for drilling holes

in masonry such as brick, concrete and similar

materials. Furthermore, the machine can be used

as a demolition hammer in combination with the

SDS cold chisels provided. The machine is on no

account intended for other purposes.

Not suitable for construction site usage.

Please inspect the machine and accessories for

transit damage.

Contents

1. Machine information

2. Safety instructions

3. Operating

4. Maintenance

1. Machine information

Technical specifications

Voltage 230 V

Frequency 50 Hz

Power rating 850 W

Rotational speed, not loaded 800/min

Impact rate 4000/min

Max. bit diameter

Concrete Ø 26 mm

Steel Ø 13 mm

Wood Ø 40 mm

Weight 4.5 kg

Lpa 83.6+3 dB(A)

Lwa 94.6+3 dB(A)

Vibration

When chiseling 17.46+1.5 m/s

2

When hammering in concrete 20.23+1.5 m/s

2

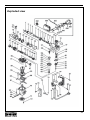

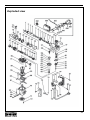

Product information

Fig. A+D

1. Rotary stop selection lever

2. On-off Switch

3. Main handle

4. Hammer stop selection lever

5. Carbon brush cap

6. Electric cord

7. Auxiliary handle

8. Depth gauge

9. Dust cap

10. Drill

11. Locking sleeve

12 Grease cap

2. Safety instructions

Explanation of the symbols

Denotes risk of personal injury, loss of life

or damage to the tool in case of non-

observance of the instructions in this

manual.

Indicates electrical shock hazard.

Wear ear and eye protection

Wear a dust mask. Working with wood,

metals and other materials may produce

dust that is harmful to health. Do not work

with material containing asbestos

Specific safety instructions

For use of this machine/tool:

Inspect the surface to be drilled for hidden •

electrical wiring, gas pipes or other obstacles

(for example, using a metal detector).

Check the following points:•

Does the appliance’s voltage correspond •

EN

4

with the mains power supply voltage?

Are power cords, insulation and plug in •

good order: sound, not loose or

damaged?

Is there a good, firm connection at the •

mains socket?

Does the drill show any sign of abnormal •

running, overheating or excessive

sparking?

Whenever any of the problems mentioned •

above appear, immediately cease using

the machine and have it repaired by an

expert.

Wear ear protectors. Exposure to noise can •

cause hearing loss.

Use auxiliary handles supplied with the tool. •

Loss of control can cause personal injury.

Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool

“live” and give the operator an electric shock.

Electrical safety

When using electric machines always observe the

safety regulations applicable in your country to

reduce the risk of fire, electric shock and personal

injury. Read the following safety instructions and

also the enclosed safety instructions.

Always check that the mains voltage is

the same as on the type plate of the

machine.

Class II machine – Double insulation –

You don’t need any earthed plug.

Replacement of power cords or plugs

Immediately dispose of old cords and plugs once

they have been replaced. It is dangerous to plug a

loose power cord into a mains power socket.

Use of extension leads

Only ever use approved extension leads that are

suitable for the power rating of the machine. The

mini mum core thickness is 1.5 mm

2

. Whenever

using a reel extension lead, always fully unroll the

lead.

Immediately switch off the machine when:

Excessive sparking of the carbon brushes and •

verticiliosis in the collector.

Interruption of the mains plug, mains lead or •

mains lead damage.

Defect switch•

Smoke or stench of scorched isolation•

3. Operating

Hammer drills require very little operator

pressure. Excessive pressure on the tool

can lead to unnecessary overheating of

the motor, and burning of the driven tool.

Auxiliary handgrip

The auxiliary handgrip can be rotated 360º around

the drill head, enabling safe and comfortable

operation, for both left and right-handed users:

Loosen the handgrip by turning it •

anticlockwise.

Rotate the handgrip to the desire position.•

Retighten the handgrip in the new position.•

Exchanging and removing drill bits

Fig. A+B

Before exchanging bits, first remove the

power plug from the wall socket.

Inspect bits regularly during use. Blunt

bits should be re-sharpened or replaced.

Lightly oil the bit shaft before inserting it into •

the chuck.

Slide the locking sleeve (11) to the rear, and •

insert the bit into the chuck opening. Ensure

that the keyway in the bit is seated properly in

the chuck, by carefully turning the bit until it

clicks into place. Release the locking sleeve.

To remove the bit, slide and hold the locking •

sleeve to the rear.

Setting depth gauge

Loosen the handgrip by turning it anticlockwise.•

Insert the depth gauge ruler through the hole •

in the auxiliary handgrip.

Slide the ruler to the desired depth.•

Retighten the screw firmly.•

Function selection switch

Fig. D

The correct position of the selection switch for

EN

5

each machine function is given in the diagram

(Fig.C) on page 2.

1 = Demolition hammer/chisel

2 = Rotary hammer drill

3 = Drilling

Switching On/Off

To start the drill, squeeze the trigger.•

To stop the drill, release the trigger.•

Installing dust catcher

Fig. C

The dust catcher prevents large amounts of

drilling dust entering the machine when drilling

into ceilings:

Remove the drill bit.•

Slide the dust catcher over the shaft of the drill •

bit.

Place the drill bit with catcher in the drill •

chuck.

Always replace a damaged dust catcher •

immediately.

4. Maintenance

Take care that the machine is not

connected to power whenever

maintenance work on the mechanical

parts is taking place.

The machines are designed to function

problem-free for a long period with a minimum

of maintenance. Through regular cleaning and

correct treatment, you help assure a long working

life for your machine.

Defects

The machine should be regularly inspected for

the following possible defects, and repaired if

necessary.

Damage to power cord•

Broken on/off trigger assembly.•

Short circuiting.•

Damaged moving parts.•

Trouble shooting

1. When switched on, the motor does not

turn.

Failure in power supply.•

Check the power supply.•

Poor contact in the on/off trigger.•

Repair or replace the trigger assembly.•

Mains voltage too low.•

Extension lead too long, or too light.•

Damaged motor.•

Have your machine repaired by an expert.•

Carbon brushes worn.•

Replace the carbon brushes•

2. Motor generates excessive noise, and

runs too slowly or not at all.

Motor is overloaded due to excessive •

pressure or drilling depth.

Reduce the pressure or drilling depth, •

reduce power.

Damaged motor.•

Have your machine repaired by an expert.•

Supply voltage too low.•

Adjust the supply voltage.•

Carbon brushes worn.•

Replace the carbon brushes•

3. Overheating in the transmission case.

Overloading of machine, or blunt drill bit•

Reduce the loading, or hone the drill bit.•

Reduced voltage.•

Adjust the supply voltage.•

4. Heavy sparking from the motor.

Inspect the carbon brushes for wear.•

Replacing carbon brushes

Replace both carbon brushes at the same •

time.

Regularly check the carbon brushes for wear •

and defects.

Always replace worn-out carbon brushes.•

Always keep the carbon brushes clean, and •

make sure that neither brush is obstructed.

Open the machine to inspect/replace the •

carbon brushes.

Remove and replace the carbon brushes if •

necessary.

Reassemble the rear handgrip.•

Cleaning

Clean the machine casings regularly with a soft

cloth, preferably after each use. Make sure that

the ventilation openings are free of dust and

dirt. Remove very persistent dirt using a soft

cloth moistened with soapsuds. Do not use any

solvents such as gasoline, alcohol, ammonia,

etc. Chemicals such as these will damage the

synthetic components.

EN

6

Lubrication

Regularly grease the hammer drill shaft. •

Regularly check the grease-level inside the •

machine:

Remove the grease cap (12) on top of the •

machine.

Remove also the second cap (with 4 •

notches)

Now you can see the rotating parts inside •

the machine: there should be grease on

the moving parts.

If necessary put some grease into the •

hole.

Place the cap onto the hole and tighten it •

again.

Mount the grease cap again.•

Faults

Should a fault occur, e.g. after wear of a part,

please contact the service address on the

warranty card. In the back of this manual you find

an exploded view showing the parts that can be

ordered.

Environment

To prevent damage during transport, the

appliance is delivered in a solid packaging which

consists largely of reusable material. Therefore

please make use of options for recycling the

packaging.

Faulty and/or discarded electrical or

electronic apparatus have to be collected

at the appropriate recycling locations.

Warranty

For the conditions of warranty, please refer to the

separately provided warranty card.

The product and the user manual are subject to

change. Specifications can be changed without

further notice.

7

8

9

DECLARATION OF CONFORMITY

EBF-850KN ROTARY HAMMER

(GB) We declare under our sole responsibility that this product

is in conformity and accordance with the following

standards and regulations:

(DE) Der Hersteller erklärt eigenverantwortlich, dass dieses

Produkt den folgenden Standards und Vorschriften

entspricht:

(NL) Wij verklaren onder onze volledige verantwoordelijk heid

dat dit product voldoet aan, en in overeenstem ming is

met, de volgende standaarden en reguleringen:

(FR) Nous déclarons sous notre seule responsabilité que ce

produit est conforme aux standards et directives

suivants:

(ES) Declaramos bajo nuestra exclusiva responsabilidad que

este producto cumple con las siguientes normas y

estándares de funcionamiento:

(PT) Declaramos por nossa total responsabilida-de que este

produto está em conformidade e cumpre as normas e

regulamentações que se seguem:

(IT) Dichiariamo, sotto la nostra responsabilità, che questo

prodotto è conforme alle normative e ai regolamenti

seguenti:

(SV) Vi garanterar på eget ansvar att denna produkt upp fyller

och följer följande standarder och bestämmelser:

(FI) Vakuutamme yksinomaan omalla vastuullamme, että

tämä tuote täyttää seuraavat standardit ja säädökset:

(NO) Vi erklærer under vårt eget ansvar at dette produktet er i

samsvar med følgende standarder og regler:

(DA) Vi erklærer under eget ansvar, at dette produkt er i

overensstemmelse med følgende standarder og

bestemmelser:

(HU) Felelősségünkteljestudatábankijelentjük,hogyeza

termék teljes mértékben megfelel az alábbi

szabványoknakéselőírásoknak:

(CS) Nanašivlastnízodpovědnostprohlašujeme,žejetento

výrobekvsouladusnásledujícímistandardyanormami:

(SK) Vyhlasujemenanašuvýhradnúzodpovednosť,žetento

výrobok je v zhode a súlade s nasledujúcimi normami a

predpismi:

(SL) S polno odgovornostjo izjavljamo, da je ta izdelek v skla-

du in da odgovarja naslednjim standardom terpredpisom:

(PL) Deklarujemynawłasnąodpowiedzialność,żetenprodukt

spełniawymogizawartewnastępującychnormachi

przepisach:

(LT) Prisiimdamivisąatsakomybędeklaruojame,kadšis

gaminysatitinkažemiaupaminėtusstandartusarba

nuostatus:

(LV) Apgalvojamarvisuatbildību,kašisproduktsirsaskaņā

un atbilst sekojošiem standartiem un nolikumiem:

(ET) Deklareerime meie ainuvastutusel, et see toode on vasta-

vuses ja kooskõlas järgmiste standardite ja määrustega:

(RO) Declarămprinaceastacurăspundereadeplinăcă

produsulacestaesteînconformitatecuurmătoarele

standarde sau directive:

(HR) IzjavljujemopodvlastitomodgovornoĻśudajestrojem

ukladansaslijedeśimstandardimailistandardiziranim

dokumentima i u skladu sa odredbama:

(SR) Podpunomodgovornošćuizjavljujemodajeusaglašen

sasledećimstandardimailinormama:

(RU) Подсвоюответственностьзаявляем,чтоданное

изделиесоответствуетследующимстандартами

нормам:

(UK) Насвоювласнувідповідальністьзаявляємо,щодане

обладнаннявідповідаєнаступнимстандартамі

нормативам:

(EL) Δηλώνουμευπεύθυναότιπροϊόναυτόσυμφωνείκαιτηρεί

τουςπαρακάτωκανονισμούςκαιπρότυπα:

(BG) Ниезаявяваме,посвоясобственаотговорност,че

тозипродукт

отговарянаследнитестандартии

директиви

EN60745-1, EN60745-2-6, EN55014-1, EN55014-2, EN61000-3-2,

EN61000-3-3

2006/42/EC, 2006/95/EC, 2000/14/EC, 2004/108/EC, 2002/96/EC, 2002/95/EC

Zwolle, 01-02-2011

I. Mönnink

CEO Ferm BV

It is our policy to continuously improve our products and we therefore reserve the right to change the

product specification without prior notice.

Ferm BV • Lingenstraat 6 • 8028 PM • Zwolle The Netherlands

10

Spare parts list

Position Description No.

102880 Steel ball 2

102881 Cylinder 3

102882 Feather key 4

102883 Piston 5

102884 O-ring 6

102885 Third gear 7

102886 Piston 8

102887 Connecting shaft 10

102888 Needle bearing 11

102904 Front selection lever 15

102889 Front cover 27

102890 Sleeve 29

102891 Second hammer 34

102892 Pinion gear 38

102893 Special nut 45

102894 Crank shaft 48

102896 Rotor 58

102898 Carbon brush holder 63

102899 Carbon brush set 64

102900 Carbon brush cap 65

102905 Rear selection lever 67

102897 Stator 69

102901 Switch 77

102902 Dust cover 501

102903 Depth limiter 504

102895 Auxiliary handle 505 TILL 509

11

Exploded view

www.ferm.com

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

Ferm HDM1024 Manual de utilizare

- Categorie

- Unelte electrice

- Tip

- Manual de utilizare

în alte limbi

- English: Ferm HDM1024 User manual

- dansk: Ferm HDM1024 Brugermanual

Lucrări înrudite

Alte documente

-

Tryton TMM1050K Manual de utilizare

-

Tryton TMM710K Manual de utilizare

-

Parkside PBH 1100 A1 Operation and Safety Notes

-

Ryobi EID750RS Manual de utilizare

-

Hikoki DH22PG Manual de utilizare

-

Parkside PBH 1050 A1 Operation and Safety Notes

-

Bavaria BRH 1208 E Instrucțiuni de utilizare

-

RIDGID 535M Manual de utilizare