Mitsubishi Electric Low-Voltage Air Circuit Breakers series Type AE-SW Manual de utilizare

- Tip

- Manual de utilizare

18A

ENGLISH

CHINESE

中文

AE630-SW AE1000-SW AE1250-SW AE1600-SW

AE2000-SWA

AE2000-SW AE2500-SW AE3200-SW

AE4000-SWA

AE4000-SW AE5000-SW AE6300-SW

本手册适用于以下型号产品

使用说明书

対象機種

三菱低压空气断路器 World Super AE

MITSUBISHI Low-Voltage Air Circuit Breakers series

World Super AE

AE-SW

ご使用の前に必ずこの取扱説明書をお読みください。

この説明書は、最終ユーザまでお届けください。

IMPORTANT NOTE:

Before using these Series AE breakers, please read these

instructions carefully, and make sure that all actual users also read them.

JAPANESE

三菱低圧気中遮断器 World Super AE

取扱説明書

Types covered in this manual

重要注释: 在使用 AE 断路器系列以前,请务必仔细阅读本说明书,

并确保所有用户也阅读本说明。

MODEL

INSTRUCTION MANUAL

2

Failure to follow these in-

structions may result in dan-

gerous conditions, which in

turn could lead to severe

personal injury or even

death.

Failure to follow these instruc-

tions may result in dangerous

conditions, which could result

in moderate to slight personal

injury or damage to equip-

ments and facilities.

Safety precautions

Warning for possible electrification under

certain conditions.

¡Do not use this device on the conditions over ratings. Otherwise, ground-fault or short circuit fault could occur due to

dielectric breakdown. Or explosion could occur due to a short circuit protection failure.

¡Do not touch the terminals. There is a risk of electrical shock.

DANGER

CAUTION

¡Before using this device, make sure to read this Instruction manual thoroughly. The cautionary items noted herein are of

the utmost importance for the safe use of this device, and should always be strictly followed.

¡Please make sure that the final user receives this Instruction manual.

¡This Instruction manual is prepared for an electrical expert.

The following symbols have been used:

This means prohibition. Never ignore this

instruction.

Warning for possible outbreak of a fire

under certain conditions.

Be sure to follow these instructions with-

out fail.

DANGER

CAUTION

¡A qualified electrician should install this equipment.

¡Inspection and maintenance should be performed by a qualified electrician and only after shutting off the electric power

and verifying that there is no voltage present. Failure to do so could result in an electrical shock.

¡Make sure to tighten the terminal screws to the torque specified in the instruction manual. Failure to do so could result

in fire.

¡Do not install in areas subject to high temperatures, high humidity, dust, corrosive gas, vibrations, or shocks, etc. To do

so could result in malfunction or fire.

¡Install so that trash, concrete dust, iron filings or rainwater cannot get into the circuit breaker unit interior. Failure to do

so could result in malfunction or fire.

¡When the circuit breaker trips automatically, always clear the source of the malfunction before closing the circuit

breaker. Failure to do so could result in fire.

¡Terminal screws should be tightened periodically. Failure to do so could result in fire.

¡Use the breaker in 50/60 Hz. Failure to do so could result in malfunction or fire.

¡Dispose of this product as industrial waste.

3

ENGLISH

Table of contents

¡Safety precautions ................................................. 2

¡External view .......................................................... 3

¡Internal construction ............................................... 4

¡Outline dimensions and Weight ............................. 4

¡Unpacking .............................................................. 5

¡Storage ................................................................... 5

¡Handling ................................................................. 6

¡Installation .............................................................. 7

¡Mount of drawout handle........................................ 8

¡Attach the Inter-phase Barrier ................................ 8

¡Connection ............................................................. 9

¡Insert operation .................................................... 11

¡Drawout operation ................................................ 13

¡Charging operation ............................................... 15

¡Opening/Closing operation .................................. 16

¡Door interlock (DI) ................................................ 18

¡Cylinder lock (CYL) and Castell lock (CAL) ......... 18

¡Shutter lock (SST-LOCK) ..................................... 19

¡Safety shutter name plate .................................... 19

¡Functions of electronic trip relay (ETR) parts ...... 20

¡Characteristics setting of type WS relay .............. 22

¡Characteristics setting of type WM relay ............. 23

¡Characteristics setting of type WB relay .............. 24

¡

Characteristic setting of optional setting module ...

25

¡Setting the operation characteristics .................... 27

¡Wiring diagram ..................................................... 29

¡

Technical note (Arc space, Reverse connection) ..

30

¡

Technical note (Performance of withstand voltage) ...

30

¡Technical note (Service conditions) ..................... 31

¡Guarantee ............................................................ 31

¡Inspection and Maintenance ................................ 32

¡Service Network ................................................... 38

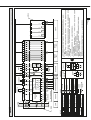

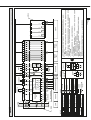

External view

< Fixed type >

Note: The fixed type is provided with lifting hooks (HP).

< Drawout type >

Fig. 3-1 Fig. 3-2

Cradle

Charging

handle

Drawout position indicator

Drawout handle aperture

Drawout handle

Extension rail

Control circuit connector

Control circuit terminal box

Drawout state

Arc-extinguish chamber

OFF button

ON buttons

Charging handle

Charging

indicator

ON/OFF

indicator

Rated name

plate

Manual reset button

(option)

Electronic trip relay

Pad lock hook

Control circuit terminal box

< Drawout type >

Fig. 3-3

4

Internal construction

1Control circuit terminal block

2Control circuit connector

3Auxiliary switch

4Shunt trip device, closing coil

5Electronic trip relay

6Front cover

7Tripping mechanism

8Closing mechanism

9Charging mechanism

AClosing spring

BDrawout mechanism

CIntermediate base

DArc-extinguishing chamber

EMovable contact

FFixed contact

GConductor on the breaker

HConductor on the cradle

IMain circuit junction

JBase

KContact spring

LConductor on the breaker

MConductor on the cradle

NPower supply CT

OCurrent sensor coil

PCradle

QCradle name plate

Table 4-1

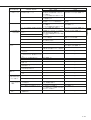

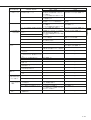

Outline dimensions and Weight

Type

AE630-SW

AE1000-SW AE1250-SW AE1600-SW

AE2000-SWA

340 ✕ 410 ✕ 290 ✕ 108

425 ✕ 410 ✕ 290 ✕ 108

300 ✕ 430 ✕ 375 ✕ 104

385 ✕ 430 ✕ 375 ✕ 104

47

57

70

84

31

35

340 ✕ 410 ✕ 290 ✕ 40

425 ✕ 410 ✕ 290 ✕ 40

300 ✕ 430 ✕ 375 ✕ 61

385 ✕ 430 ✕ 375 ✕ 61

40

50

63

77

42

52

65

79

41

51

64

78

26

30

Dimension

a ✕ b ✕ c ✕ d

(mm)

3P

4P

3P

4P

3P

4P

3P

4P

3P

4P

Weight

(kg)

Fixed

type

Drawout

type

Fixed

type

Drawout

type

Cradle

only

Table 4-2

Type AE2000-SW AE2500-SW AE3200-SW

60

72

92

113

35

43

61

73

93

114

63

75

95

116

36

44

AE4000-SWA

475 ✕ 410 ✕ 290 ✕ 117

605 ✕ 410 ✕ 290 ✕ 117

439 ✕ 430 ✕ 375 ✕ 109

569 ✕ 430 ✕ 375 ✕ 109

81

99

108

136

49

61

475 ✕ 410 ✕ 290 ✕ 40

605 ✕ 410 ✕ 290 ✕ 40

435 ✕ 430 ✕ 375 ✕ 61

565 ✕ 430 ✕ 375 ✕ 61

Dimension

a ✕ b ✕ c ✕ d

(mm)

3P

4P

3P

4P

3P

4P

3P

4P

3P

4P

Weight

(kg)

Fixed

type

Drawout

type

Fixed

type

Drawout

type

Cradle

only

AE-SW

Fig. 4-1

¡Drawout type

Fig. 4-3

Fig. 4-4

¡Fixed type

Fig. 4-2

b

acd11

43

15 c d

40

a (MAX)

b

Drawout handle aperture

Drawout handle

Max.173

200

Cover position

169

200

Type

Dimension

a ✕ b ✕ c ✕ d

(mm)

Weight

(kg)

Fixed

type

Drawout

type

Fixed

type

Drawout

type

Cradle

only

AE4000-SW AE5000-SW AE6300-SW

233

256

(

279

)

118

133

(

148

)

240

263

(

286

)

125

140

(

155

)

874 ✕ 414 ✕ 290 ✕ 136

1004

(

1134

)

✕ 414 ✕ 290 ✕ 136

875 ✕ 480 ✕ 375 ✕ 123

1005

(

1135

)

✕ 480 ✕ 375 ✕ 123

160

180

(

200

)

3P

4P

3P

4P

3P

4P

3P

4P

3P

4P

Table 4-3

( ) shows the value for 4P FN type, Neutral pole current capacity is 100% of the rated current.

5

ENGLISH

Accessories

nameplate

ETR accessories

Nameplate

CT rated

name plate

Rated

name plate

Storage

Unpacking

Fig. 5-1

1 Make sure that the packing case is free from any abnormality such as

breaking and/or wetting.

2 Referring to the rating nameplate, make sure that the delivered breaker

is in conformity with your order. Serial No. is indicated on the rated

name plate and the cradle name plate (Fig. 4-1Q).

Fig. 5-2 Fig. 5-3

Fig. 5-4

✽ When you start using the breaker after storage and if its storage period is over 6 years, use the ACB after grease lubrication.

Please contact to our service network how to grease.

Fig. 5-5 Fig. 5-6 Fig. 5-7

Fig. 5-8 Fig. 5-9

Fig. 5-10

Fig. 5-11

Fixed type Drawout type

OFF

+60°C

–20°C

H

2S ≤ 0.01ppm

SO2 ≤ 0.05ppm

NH3 ≤ 0.25ppm

Not attached

Average temperature for 24 hours,

however, shall not be higher than 35°C.

Avoid humid air.

Relative humidity : 85% max.

6

Handling

Fig. 6-1

Lifting hooks (HP)

Fig. 6-2

Never drop the breaker when

handling.

Never roll the breaker

when handling.

Fig. 6-3

Fixed type

Fig. 6-4

When the drawout breaker is

lifted with the cradle, lift it

when it is the “CONNECT”

position.

Drawout type

Fig. 6-5

When lifting and placing, be careful nei-

ther to drop nor to impact the breaker and

the terminals for the center of gravity is

by the terminal.

CONNECT position

Wire length: 1 m or more Wire length: 1 m or more

Fig. 6-6

To lift the breaker types AE4000-SW,

AE5000-SW and AE6300-SW, be sure to

use four ropes with a length of 1 m or

more, or use the lifting truck, apply for

further detail.

length ≥ 1 m

7

ENGLISH

Installation

Tolerance on support flatness ≤ 1 mm

1 mm or less

Fig. 7-1

< Drawout type >

Fig. 7-2

M8

Earthing terminal

M12

M8

Earthing

terminal

M12

Fig. 7-8

< Fixed type >

Operate the drawout operation (CONNECT position to DRAWOUT position) according to instructions of drawout

operation. (Refer to P.13 and 14.)

Lifting by lifting truck or lifting hooks

Fig. 7-5

Fig. 7-6

CAUTION

Fig. 7-7

Lifting

Falling

On AE4000-SWA,AE4000-SW ~

AE6300-SW, the center of gravity of the

cradle is located at the terminal posi-

tion. When the main body is removed

from the cradle, the cradle may turn over

backward. Take measures against

overturning.

When the main body is drawn out,

the center of gravity shifts to the

front. If the cradle is not secured,

take measures against overturning

and dropping.

CAUTION

Fig. 7-3 Fig. 7-4

In the case of AE4000 ~ 6300-SW, insert four M12 bolts from the bottom and two M12 bolts from the back to mount the

cradle as shown in Fig. 7-3. In the case of 4P FN type, insert six M12 bolts from the bottom and two M12 bolts from the

back to mount the cradle as shown in Fig. 7-4.

AE4000 ~ 6300-SW 3P & 4P (HN) AE4000 ~ 6300-SW 4P (FN)

Mounting angle (Non-magnetic)

2-M12

6-M12

2-M12

4-M12

Mounting angle (Non-magnetic)

Cradle

Support

8

Fig. 8-1 Fig. 8-2

Fig. 8-4

Note: The drawout handle cannot be mounted

on the left side of the cradle when the

cradle is provided with a mechanical

inter lock (MI) or a door inter lock (DI).

Mount the handle at an appropriate

position in the panel.

Cradle

Handle holder

Drawout handle

Mtg. Screw M5 ✕ 12

2.8 ~ 3.6 N·m

Nut M5

Mechanical interlock (MI)

or

door interlock (DI)

¡Mounting on the left side ¡Mounting on the right side

Mount of drawout handle

The drawout handle can be mounted on any of the left and right sides of the cradle.

Attach the Inter-phase Barrier

Insert in the slot on the breaker.

Fig. 8-3

<Fixed type> <Drawout type>

Fig. 8-5

9

ENGLISH

M3.5 ✕ 10

Torque: 0.8 ~ 1.2Nm

Max. 200 mm

Fixing support

25mm

Connection

■Main circuit

Fig. 9-1

Use small washers to connect that

the washers do not overlap with

each other.

Fig. 9-3

Fig. 9-2

M12

40 ~ 50N·m

Conductor

If the screw is tightened with exces-

sive torque, the terminal and the

screw may be damaged. Tighten

the screw to the specified torque.

Screwdrivers should be used whose

diameters are of size suited to the

diameters of the cruciform grooves.

Size of toolhead : PH2

Fig. 9-4

■Control circuit

¡Crimp-type terminal size

Recommended crimp-type terminals

Ex.1.25 mm

2

~ 2.0 mm

2

wires

N2-M3(RAP2-3.5) (JST)

FN2-M3(RBP2-3.5) (JST)

N2-YS3A(JST)

Fig. 9-5 Fig. 9-6 Fig. 9-7

Passage wiring

Max. 7.2 mm

ACB termi-

nal (silver-

plated)

CAUTION CAUTION

CAUTION

10

Table 10-1 Electromagnetic force in N per 1 m conductor (3-phase short circulation)

Type

Conductor distance (mm)

Prospective fault current

kA (pf)

(N)

Drawout type Fixed type

30 (0.2)

42 (0.2)

50 (0.2)

65 (0.2)

75 (0.2)

85 (0.2)

100 (0.2)

130 (0.2)

AE630-SW

~

AE1600-SW

85

7,700

15,100

21,400

36,100

—

—

—

—

3P

115

5,700

11,200

15,800

26,700

—

—

—

—

4P

105

6,300

12,200

17,300

29,300

—

—

—

—

3P

190

3,500

6,800

9,600

16,200

21,500

27,600

—

—

4P

170

3,900

7,600

10,700

18,100

24,100

30,900

—

—

3P

152

4,300

8,500

12,000

20,200

26,900

34,500

—

—

4P

145

4,500

8,900

12,600

21,200

28,200

36,200

—

—

AE2000-SWA

AE4000-SWAAE2000-SW

~

AE3200-SW

130

5,100

9,900

14,000

23,600

31,500

40,400

—

—

AE4000-SW

~

AE6300-SW

262

2,500

5,000

7,000

11,800

15,800

20,000

27,800

47,000

Table 10-2

Conductor size (IEC60947-1)

(40°C ambient temperature, open air)

Note: Table 10-2 shows conductor size based

on IEC 60947-1 in ambient temperature

40°C and open air. And the examination

circuit is as Fig. 10-1

Rated current max. (A)

630

1000

1250

1600

2000

2500

3200

4000 (AE4000-SW)

5000

6300

Arrangement

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Connecting conductors (Copper bus bar)

Quantity

2

2

2

2

3

4

3

3

4

4

4

4

Conductor size (mm)

40 ✕ 5

60 ✕ 5

80 ✕ 5

100 ✕ 5

100 ✕ 10

150 ✕ 10

100 ✕ 10

150 ✕ 10

200 ✕ 10

AE4000-SWA

Fixed type

AE4000-SWA

Drawout type

4000

4000

Fig. 10-1

3m

2m

11

ENGLISH

Using a lifter or ropes

Insert operation

■DISCONNECT → CONNECT position

1 Release the lock levers, and pull the extension rails for-

ward.

2 Place the breaker on the extension rails, using a lifter or

ropes. Mount the concave of the breaker in the rail pro-

truding portion. (Fig. 11-5)

Fig. 11-1

1

3 Slowly push the breaker in unit it does not move.

To insert the breaker, push each side equally.

Otherwise (in the case of inserting slantwise) the breaker

can not move smoothly.

When ACB is installed at a high position, please do the

Drawout / Insert operation by two people.

Fig. 11-3

3

4 Keeping the OFF button pushed, insert the drawout handle.

Make sure that the drawout position indicator shows “DIS-

CONNECT” (Fig. 11-7).

Fig. 11-2

2

Falling

Shut finger

Take care not to shut finger be-

tween extension rails and switch

board when the breaker is insert.

DISCONNECT position

(Prohibition)

Do not insert the drawout handle unless the OFF but-

ton is pushed.

There is a possibility of damaging.

Extension rails

Lock levers

Click!

Concave of the breaker

Projection of the rail

Fig. 11-5

Fig. 11-4

Fig. 11-7

If the breaker main body is put

on the rails with the cradle un-

secured, the center of gravity

shifts to the front. Take mea-

sures against overturning.

CAUTION

CAUTION

4

OFF button

Push

Insert

Drawout handle

Fig. 11-6

12

TEST position

Latch

Release

position

Cover

Push

Lock plate

Lock position

5 Push the lock plate in fully until it is latched to release

the lock.

(Note:)

(a) If the lock plate is not fully released, turn the

drawout handle to right and left a little.

(b) Be sure to push the lock plate in fully to release

position, otherwise the drawout position indicator

may not function collectoly.

Fig. 12-1

7 When the breaker is inserted to the test position, the

drawout position indicator shows TEST position, and the

lock plate automatically protrudes to lock the drawout

handle.

Fig. 12-3

7

Insert the breaker until the lock plate protrudes. If it does

not protruding, the breaker may not be connected com-

pletely.

6 After releasing the lock plate, turn the drawout handle

clockwise.

(Note:)

(a) Do not try to pull the unit out while inserting it as

doing so may not accurately display the posi-

tion. If the unit is pulled out in the middle of the

inserting process, pull it out to the circuit dis-

connecting position and then insert it again.

Fig. 12-2

6

8 Then, push the lock plate to turn the handle clockwise.

When the breaker is inserted to the connect position,

the lock plate automatically protrudes to indicate that

the breaker has been inserted completely. The drawout

position indicator shows CONNECT position.

(Note:)

(a) After insertion is completed, do not turn the

drawout handle further.

(b) The drawout position indicator shows the position

(CONNECT or TEST) of the breaker at the time

when the lock plate protrudes. When the lock

plate is in the released state, the indicator shows

the reference position.

(c) It is impossible to close the breaker when insert-

ing the drawout handle.

8

Check 1

The lock plate is jutted

out.

Automatic

Check 2

CONNECT (Connection)

position

Fig. 12-4

CAUTION

5

9

Fig. 12-5

9 For the AE4000 ~ 6300-SW series (See Fig. 12-5), shall

be sure to tighten the screws on both sides to secure

the breaker.

13

ENGLISH

OFF button

Push

Drawout handle

Drawout operation

2 Keeping the OFF button pushed, insert the drawout

handle.

Fig. 13-3

2

(Prohibition)

Do not insert the drawout handle unless the OFF

button is pushed.

3 Push the lock plate in fully until it is latched to release

the lock.

(Note:)

(a) If the lock plate is not fully released, turn the

drawout handle to right and left a little.

(b) Be sure to push the lock plate in fully to the re-

lease position, otherwise the drawout position in-

dicator may not function correctly.

4 After releasing the lock plate, turn the drawout handle

counterclockwise.

(Note:)

(a) In the middle of drawout operation, do not turn

the drawout handle insert operation. The drawout

position indicator may not function correctly.

In this case, pull the unit out to the circuit discon-

necting position and insert it to the circuit con-

necting position. Then drawout it again.

CONNECT position

Fig. 13-2

1

Fig. 13-1

1 Remove two fixing bolts (M12) for the types AE4000 ~

6300-SW. (See Fig. 13-1)

■CONNECT → DISCONNECT position

Lock plate

Latch

Cover

Push

Lock position

Release

position

Fig. 13-4

3

Fig. 13-5

4

14

Click!

Lock lever

TEST position

Automatic

5 When the breaker is drawn out to the test position, the

drawout position indicator shows TEST position, and the

lock plate automatically protrudes to lock the drawout

handle.

Fig. 14-1

5

6 Then, push in the lock plate, turn the drawout handle

counterclockwise to change the displayed extraction

position to the DISCONNECT position until the drawout

position indicator shows disconnect position. The handle

operation is completed. The breaker can be drawn out

by hand.

(Note:)

(a) The lock plate may project before the breaker

moves to the DISCONNECT position. Push the

lock plate in and continue to operate the handle.

(b) If the lock plate is not fully released, turn the

drawout handle to right and left a little.

(c) When the breaker is drawn out to the DISCON-

NECT position, the drawout handle is idly rotated

and the lock plate does not protrude.

7 To remove the breaker main body from the cradle, pull

the lock levers toward you to unlock the main body, pull

the rails toward you, and draw out the breaker.

Fig. 14-2

6

Fig. 14-4

7

Take care not to shut finger be-

tween extension rails and switch

board when the breaker is

drawn out.

Shut finger

Falling

DISCONNECT

position

Fig. 14-3

When the main body is drawn

out, the center of gravity shifts

to the front. If the cradle is not

secured, take measures against

overturning and falling.

CAUTION

CAUTION

15

ENGLISH

Charging operation

Fig. 15-3

¡Manual charging operation is also possible using the charg-

ing handle.

¡Although the charging motor has a short time rating it can

be continuously operated for up to ten times.

¡Since the charging complete switch is separate from the

motor charging circuit, the sequence can be arranged as

required.

Fig. 15-2

Table 15-1 Motor charging rating

< Motor charging >

The closing spring is electrically charged.

This is an “ON charge method”, in which the spring is auto-

matically charged when the breaker is closed.

Rated

voltage

(V)

Applicable

voltage

range (V)

Applied

voltage

(V)

Inrush

current

(peak) (A)

Steady

current

(A)

Charging

time

Criterion for

power

requirement

(VA)

24 DC

48 DC

100-125

AC/DC

200-250

AC/DC

18-26.4

36-52.8

85-137.5

170-275

24

48

100

125

200

250

22

14

10 (10)

12 (12)

5 (7)

6 (8)

6

3

3 (4)

3 (4)

1 (2)

1 (2)

5 sec or

less

500

700

1000

700

1000

Note 1: Contents in parentheses show the case of AE4000-SWA 4-pole,

AE4000-SW, AE5000-SW and AE6300-SW.

24 V DC and 48 V DC products of AE4000-SWA 4-pole, AE4000-SW,

AE5000-SW and AE6300-SW cannot be manufactured.

Note 2: Operating power supply capacity of the motor charging should be

prepared not to be lower than an applicable voltage range during

charging.

< Manual charging >

Press the charging handle down at full stroke 7 or 8 times

until a click sounds. (It is completion when a charging handle

becomes light.) Then, the closing spring will be fully charged.

The charging indicator will show CHARGED.

The operating load is 30 N·m or less.

Charge operation: 7 to 8 times

MD circuit diagram

Charging

completion

Switch output

M

Apply for further of 24 V DC and 48 V DC.

Breaker

Control

relay

Motor charging

circuit

Charging limit

switch

Charging completion switch

Motor

Control

supply

413

414

U1

U2

8 To drawout the breaker, pull each side equally.

Otherwise (in the case of drawing slantwise) the breaker

can not move smoothly.

When ACB is installed at a high position, please do the

Drawout / Insert operation by two people.

(Note:)

Since the center of gravity is by the terminal, the

Cradle support is required to prevent from falling.

(See Fig. 15-1)

Fig. 15-1

8

Cradle support

16

Fig. 16-1

Opening/Closing operation

< Conditions of ON operation >

ON operation will be possible, when all the following condi-

tions have fulfilled.

Manual operation

< Closing >

Push the ON button, the breaker will close. The ON/OFF

indicator will show “ON”, and the charging indicator will show

“DISCHARGED”. Operating force is less than 50N.

(Note:)

When the OFF lock device (Padlock, cylinder lock,

castell lock etc.) is used, the closing operation should

be made after the lock is released.

Opening and closing of the drawout type breaker

must be carried out in either the CONNECT or the

TEST position.

If an under voltage trip device (UVT) is provided, its

rated voltage should be applied before attempting to

close and open the breaker.

< Opening >

Push the OFF button, the breaker will be opened and the

ON/OFF indicator will show “OFF”. Operating force is less

than 50N.

Fig. 16-2

Fig. 16-3

OFF

non-OFF instructions

ON

ON

OFF

OFF

¡The breaker is OFF condition.

¡The closing spring is charged.

The charging indicator shows “CHARGED”.

¡The state without OFF operations.

•

Without SHT operation

•Without mechanical lock (Padlock, Cylinder lock, Mechanical in-

terlock etc.)

•UVT controller power is supplied and no operation with trip ter-

minals.

17

ENGLISH

Control supply

Fig. 17-1

Power supply

A1

A2

Air circuit breaker

Min. 80ms

CC Unit

CC

One pulse

circuit

Note: 24 to 48 V DC does not have rectifier circuit.

SHT circuit diagram

Fig. 17-2

Note: 24 to 48 V DC does not have rectifier

circuit.

Power supply

Air circuit breaker Cut-off

switch

SHT unit

SHT

C1

C2

Min. 40ms

UVT circuit diagram (for 380-460 V AC)

Fig. 17-4

UVT circuit diagram (for 100-120 V AC, 200-240 V AC or

DC voltage)

Fig. 17-3

Note: Use a pushbutton for tripping having power ratings of

150 V DC and 0.5 A or more.

D1

D2

UVT

controller

UVT

coil

Push button

for tripping

Min 0.2s

Max. 2m

Air circuit breaker

DT1

DT2

D1

D2

IN1

IN2

OUT3

OUT4

UVT

controller

UVT

coil

External

unit

Air circuit breaker

Note: Use a pushbutton for tripping having power ratings of

150 V DC and 0.5 A or more.

The external transformer dedicated for AE-SW is used.

Only one UVT controller can be connected to one

external unit.

Max. 2m

DT1

DT2

Push button

for tripping

Min 0.2s

Electrical operation

< Closing >

Remote closing can be made by emerging the closing coil (CC).

Apply the rated voltage to the control terminals A1 , A2 , and

the breaker closes.

The unit comprises an unti-pumping circuit which allows only

one action without first de-energizing then re-energizing.

To re-close the breaker, once turn off power (between A1 and

A2 ) to the closing coil, and re-apply the rated voltage to them.

When the breaker has an under-voltage trip device (UVT), the

breaker cannot be closed if power is not applied. (After power is

applied to the UVT, it takes a waiting time of 1.5 sec until the

breaker can be closed.)

< Opening >

The use of a shunt trip device (SHT) or an under-voltage trip

device (UVT) enables to electrically trip the breaker.

When an SHT is used, apply the rated voltage to C1 and C2 on

the control circuit terminal block.

When a UVT is used, open the trip terminals DT1 and DT2 on

the control circuit terminal block. (A short-circuiting bar has been

fitted before shipment. Remove the bar before using the termi-

nals.)

Or turn off an applied voltage to D1 and D2 .

18

< Procedures for releasing door interlock >

1 Even when the breaker is on, the interlock can be manually released.

For this purpose, make a hole 7 or more in diameter in the panel door. (See the following figure.)

Release

Door

5

When the breaker is on

(5)

40

20

View A

Door hook

Direction A

Hole for releasing 7 or

more in diameter

Cylinder lock (CYL) and Castell Lock (CAL)

< Procedures for locking in off state >

1 Press the OFF button to turn off the ACB.

2 Hold down the OFF button and turn the key to the locking

side. Then, the key can be removed, and the breaker will

be locked in the off state.

Door interlock (DI)

Lock

OFF

OFF

OFF

OFF

< Releasing procedures >

1 Insert the key, and turn the key to the releasing side.

If the key cannot be turned smoothly, hold down the OFF

button and turn the key to the releasing side.

Release

OFF

OFF

Fig. 18-1

Fig. 18-2

Fig. 18-3

Fig. 18-4

(mm)

19

ENGLISH

Shutter lock (SST-LOCK)

The safety shutter can be locked at the closing position so that

the live parts are not touched.

Prepare a pad lock (5 in diameter) by yourself.

Pad lock (f5)

Shutter lock

Fig. 19-1

Safety shutter name plate

Please refer to a lower figure, if you need to attach the sticker “BUSBARS” and “CABLES” included in the package of the safety shutter.

Fig. 19-2

Bundled name plate

Bundled name plate

20

< Functions >

1 ERR. LED, Contact alarm output

When any abnormality or setting failure is found in ETR,

the LED alerts the operators to the abnormal status. When

the power type is P3 to P5, contact output is given be-

tween

513

and

574

on the control circuit terminal block.

•ETR function (Microprocessor, H/W)

•Mis-setting of INST. /MCR dial (P.27)

•Internal wiring of breaker related to ETR

2 RUN LED (ETR)

This LED indicates that ETR is functional. When control

power is applied or approx. 10% of current flows into the

main circuit, the internal circuit will start, and the LED will

light.

3 RUN LED (Optional setting module)

This LED indicates that the optional setting module is func-

tional.

When the control power is applied or approx. 10% of the

main circuit current flows, the LED will light.

4 Trip indicator (LED and contact alarm output)

The LED indicates the tripping or pre-alarm status. When

the power supply type is P3 to P5, contact output is given

between

513

(common) and

524

,

534

,

544

and

554

on

the control circuit terminal block.

When the current exceeds pre-alarm current setting (Ip),

the PAL LED will blink. When the LTD time (1/2 of TL) is

passed, the PAL LED will light and output the contact.

As for the display and interface unit, see the separate instruction manual.

3RUN LED

(GFR)

5TAL LED

4LED indicating

cause of tripping

4LED indicating

cause of tripping

1ERR. LED

2RUN LED

(ETR)

7RESET

button

6MCR

Do not

set

5 TAL LED and contact output

Option

The ETR temperature detector is made functional by fit-

ting a TAL sensor.

When the power type is P3 to P5, output is given between

513

and

564

on the control circuit terminal block. When

the temperature drops, the output will be reset. To retain

the output, take measures with an external sequence.

6 MCR (Making current release)

Option

Only when the breaker is turned on (from the off state), it

has the INST function. After it is turned on, the INST func-

tion will be disabled. If you specify the use of MCR when

placing an order, the MCR switch will be incorporated in

the main body. MCR will be functional by setting the INST

setting dial of ETR to the MCR side. (Refer to Fig. 20-2)

7 Reset button

The trip indicator (LED and contact alarm output) can be

reset by pressing the “RESET” button on the front panel

of ETR or short-circuiting

RS1

and

RS2

on the control cir-

cuit terminal block.

(P1 and P2 types are not provided with the function to

reset the indication from the control circuit terminal block.)

A function is provided to temporarily lock LTD and STD

when the INST function is tested with the field test device.

(See the breaker tester instruction manual.)

Fig. 20-1

Functions of electronic trip relay (ETR) parts

Fig. 20-2

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

Mitsubishi Electric Low-Voltage Air Circuit Breakers series Type AE-SW Manual de utilizare

- Tip

- Manual de utilizare

în alte limbi

Alte documente

-

Phcbi MPR-514R Instrucțiuni de utilizare

-

Rittal SK 3303.470 Assembly And Operating Instructions Manual

-

Rittal Blue e+ Assembly And Operating Instructions Manual

-

Eaton CEAG ZB-S Mounting And Operating Instructions

-

Yamaha P2150 Manualul proprietarului

-

Yamaha P2075 Manualul proprietarului

-

Miele APWM 061 Manual de utilizare

-

Suzuki Jimny Manualul proprietarului

-

Samsung HT-D6750WK Manual de utilizare

-

Samsung HT-D7500W Manualul utilizatorului