Ferm AGM1048 Manual de utilizare

- Categorie

- Polizoare unghiulare

- Tip

- Manual de utilizare

www.ferm.com

Angle Grinder

AGM1048

EN

Original instructions

04

2

5

1

3

6

4

2 Ferm

Fig. A

2 Ferm

4

3

10

9

7

8

1112

4

2

3

Ferm

Fig. B

3

Ferm

13

6

13

6

4 Ferm

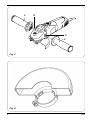

Fig. C

Fig. D

EN

5

Ferm

ANGLE GRINDER

Thank you for buying this Ferm product.

By doing so you now have an excellent product,

delivered by one of Europe’s leading suppliers.

All products delivered to you by Ferm are

manufactured according to the highest standards

of performance and safety. As part of our

philosophy we also provide an excellent customer

service, backed by our comprehensive warranty.

We hope you will enjoy using this product for many

years to come.

Safety warnings

WARNING

Read the enclosed safety warnings, the

additional safety warnings and the

instructions. Failure to follow the safety

warnings and the instructions may result

in electric shock, fire and/or serious

injury. Keep the safety warnings and the

instructions for future reference.

The following symbols are used in the user manual

or on the product:

Risk of personal injury.

Risk of electric shock.

Immediately remove the mains plug from

the mains if the mains cable becomes

damaged and during cleaning and

maintenance.

Risk of flying objects. Keep bystanders

away from the work area.

Wear ear and eye protection

Wear protective gloves

Do not press the spindle lock button while

the motor is running.

Risk of fire.

Double insulated.

Additional safety warnings for angle grinders

The machine has been designed for use as a •

grinder or cut-off machine. The machine is not

suitable for operations such as sanding, wire

brushing, polishing, etc. Risk of personal

injury.

Do not use accessories which are not •

specifically designed and recommended by

the manufacturer. Risk of personal injury.

Inspect the machine and the accessories •

before each use. Do not use accessories

which are bent, cracked, or otherwise

damaged. If the machine or one of the

accessories is dropped, inspect the machine

or the accessory for damage. If necessary,

replace the accessory.

Let the machine run at no load in a safe area •

after mounting the accessories. If the machine

vibrates strongly, immediately switch off the

machine, remove the mains plug from the

mains, and try to solve the problem.

Make sure that the maximum speed for the •

grinding disc is larger than or the same as the

maximum speed of the machine. Refer to the

rating plate on the machine.

Only use grinding discs with the correct •

thickness and outside diameter. Refer to the

rating plate on the machine.

Make sure that spindle diameter of grinding •

discs, spacers, tension nuts, etc. correspond

to the diameter of the spindle on the machine.

Make sure that the grinding disc is properly •

mounted. Do not use adapters or other aids to

mount grinding discs with another spindle

diameter.

Only use grinding discs that are recommended •

by the manufacturer. Only use guards that are

specifically designed for the grinding disc.

Only use grinding discs that are suitable for •

the application. For example: do not grind with

the side of a cut-off disc.

EN

6 Ferm

Do not use the machine without the guard. •

Securely mount the guard for maximum

safety. Make sure that the user is protected

from the grinding disc as much as possible.

Make sure that the workpiece is properly •

supported or fixed.

Wear safety goggles. Wear hearing protection. •

Wear a dust mask. If necessary, use other

protective means, such as safety gloves,

safety shoes, etc. Risk of personal injury.

Keep bystanders away from the work area. •

Make sure that all persons in the work area

wear protective equipment. Risk of personal

injury.

Keep the mains cable away from the rotating •

grinding disc. If the mains cable touches the

rotating grinding disc, your hands or arms may

come in contact with the grinding disc.

Risk of personal injury.

Hold the machine by the insulated gripping •

surfaces where the grinding disc may contact

hidden wiring or the mains cable. If the

grinding disc contacts a ’live’ wire, the

exposed metal parts of the machine can also

become ’live’. Risk of electric shock.

Do not use the machine while carrying it at •

your side. Risk of personal injury.

Do not use the machine on workpieces •

requiring a maximum grinding depth that

exceeds the maximum grinding depth of the

grinding disc.

Do not use accessories that require liquid •

coolants. Risk of electric shock.

Do not use the machine near flammable •

materials. Risk of fire.

Do not work materials containing asbestos. •

Asbestos is considered carcinogenic.

Do not work metal with a magnesium content •

of more than 80%.

Beware that the grinding disc continues to •

rotate for a short period after switching off the

machine. Do not attempt to bring the grinding

disc to a standstill yourself.

Never put the machine down on a table or •

a workbench before it has been switched off.

Regularly clean the ventilation slots. •

Risk of electric shock.

Kickback is a sudden reaction to a pinched, bound

or twisted grinding disc, which causes the machine

to lift up and out of the workpiece towards the user.

If the grinding disc is pinched or bound tightly by

the cut, the grinding disc jams and the machine is

rapidly driven back towards the user. If the

grinding disc is twisted in the cut, the back edge of

the grinding disc can dig into the top surface of the

workpiece, which causes the grinding disc to climb

out of the cut and jump back towards the user.

Kickback is the result of incorrect use of the

machine and/or incorrect operating procedures or

conditions. Kickback can be avoided by taking

proper precautions:

Firmly hold the machine with both hands. •

Position your arms to resist kickback forces.

Position your body to either side of the

grinding disc, but not in line with the grinding

disc. Kickback can cause the grinding disc to

jump backwards. If proper precautions are

taken, kickback forces can be controlled by

the user.

Be extra careful when using the machine on •

corners, sharp edges, etc. Make sure that the

grinding disc does not become jammed.

Risk of kickback.

If the grinding disc jams or if you interrupt a cut •

for any reason, release the on/off switch and

hold the machine motionless in the material

until the grinding disc comes to a complete

standstill. Never attempt to remove the

machine from the workpiece or pull the

machine backward while the grinding disc is in

motion. Risk of kickback.

Do not use blunt or damaged grinding discs. •

Unsharpened or incorrectly mounted grinding

discs produce narrow cuts, which causes

excessive friction and kickback and increases

the risk of the grinding discs becoming

jammed.

Do not use toothed saw blades. Do not use •

woodcarving blades for saw chains.

Risk of personal injury.

Electrical safety

Always check that the voltage of the

power supply corresponds to the voltage

on the rating plate.

Do not use the machine if the mains cable or •

the mains plug is damaged.

Only use extension cables that are suitable for •

the power rating of the machine with a

minimum thickness of 1.5 mm

2

. If you use a

extension cable reel, always fully unroll the

cable.

EN

7

Ferm

Mains plug replacement (UK only)

If the moulded 3-pin plug attached to the unit is

damaged and needs replacing, it is important that

it is correctly destroyed and replaced by an

approved BS 1363/5A fused plug and that the

following wiring instructions are followed.

The wires in the mains cable are coloured in

accordance with the following code:

blue neutral

brown live

As the colours of the wires in the mains cable of

the unit may not correspond to the coloured

markings identifying the terminals in the plug,

proceed as follows:

- The wire which is coloured blue must be

connected to the terminal which is marked

with the letter N or coloured black.

- The wire which is coloured brown must be

connected to the terminal which is marked

with the letter L or coloured red.

Technical data

Mains voltage 230-240 V~

Mains frequency 50 Hz

Power input 500 W

No-load speed 11,000 /min

Grinding disc Ø 115 mm

Bore Ø 22 mm

Spindle thread M14

Weight 1.5 kg

Sound pressure (Lpa) 86 dB(A)

Acoustic power (Lwa) 97 dB(A)

Uncertainty (K) 3 dB(A)

Vibration 3.13 m/s

2

Uncertainty (K) 1.5 m/s

2

Vibration level

The vibration emission level stated in this

instruction manual has been measured in

accordance with a standardised test given in EN

60745; it may be used to compare one tool with

another and as a preliminary assessment of

exposure to vibration when using the tool for the

applications mentioned

- using the tool for different applications, or with

different or poorly maintainted accessories,

may significantly increase the exposure level

- the times when the tool is switched off or when

it is running but not actually doing the job, may

signifi cantly reduce the exposure level

Protect yourself against the effects of

vibration by maintaining the tool and its

accessories, keeping your hands warm, and

organizing your work patterns

Wear ear and eye protection

Description

Fig. A

Your angle grinder has been designed for grinding

and cutting masonry and steel.

This machine, in combination with the

included grinding guard, is only suitable

for grinding operations. Cutting

operations with bonded abrasive cut-off

wheels are only allowed when a cut-off

guard (Fig D, available as optional

accessory 300802) is used.

1. On/off switch

2. Spindle lock button

3. Carbon brush cap

4. Guard

5. Main grip

6. Auxiliary grip

Assembly

Before assembly, always switch off the

machine and remove the mains plug from

the mains.

Mounting and removing the guard

Fig. B

Do not use the machine without the

guard.

Mounting

Place the machine on a table with the spindle •

(3) facing upwards.

Keep the spindle lock button (2) pressed and •

remove the flange (7) using the flange key (8).

If necessary, remove the grinding disc (9).•

Remove the flange (10).•

Mount the guard (4). Secure the guard (4) by •

tightening the screw (11) and the nut (12).

Mount the flange (10).•

If necessary, mount the grinding disc (9).•

EN

8 Ferm

Keep the spindle lock button (2) pressed and •

mount the flange (7) using the flange key (8).

Removing

Place the machine on a table with the spindle •

(3) facing upwards.

Keep the spindle lock button (2) pressed and •

remove the flange (7) using the flange key (8).

If necessary, remove the grinding disc (9).•

Remove the flange (10).•

Remove the guard (4) by loosening the screw •

(11) and the nut (12).

Mount the flange (10).•

If necessary, mount the grinding disc (9).•

Keep the spindle lock button (2) pressed and •

mount the flange (7) using the flange key (8).

Mounting and removing the grinding disc

Fig. B

Do not use the machine without the

guard.

Mounting

Place the machine on a table with the guard •

(4) facing upwards.

Keep the spindle lock button (2) pressed and •

remove the flange (7) using the flange key (8).

Mount the grinding disc (9).•

Keep the spindle lock button (2) pressed and •

mount the flange (7) using the flange key (8).

Removing

Place the machine on a table with the guard •

(4) facing upwards.

Keep the spindle lock button (2) pressed and •

remove the flange (7) using the flange key (8).

Remove the grinding disc (9).•

Keep the spindle lock button (2) pressed and •

mount the flange (7) using the flange key (8).

Mounting and removing the auxiliary grip

Fig. C

Mounting

Tighten the auxiliary grip (6) into one of the •

mounting holes (13).

Removing

Loosen the auxiliary grip (6) from the mounting •

hole (13).

Use

Switching on and off

Fig. A

To switch on the machine in continuous mode, •

slide the on/off switch (1) in the direction of the

grinding disc.

To switch off the machine, press the lower part •

of the on/off switch (1).

Hints for optimum use

Clamp the workpiece. Use a clamping device •

for small workpieces.

Draw a line to define the direction in which to •

guide the grinding disc.

Hold the machine with both hands.•

Switch on the machine.•

Wait until the machine has reached full speed.•

Place the grinding disc on the workpiece.•

Slowly move the machine along the pre-drawn •

line, firmly pressing the grinding disc against

the workpiece.

Do not apply too much pressure on the •

machine. Let the machine do the work.

Switch off the machine and wait for the •

machine to come to a complete standstill

before putting the machine down.

Cleaning and maintenance

Before cleaning and maintenance, always

switch off the machine and remove the

mains plug from the mains.

Regularly clean the housing with a soft cloth.•

Keep the ventilation slots free from dust and •

dirt. If necessary, use a soft, moist cloth to

remove dust and dirt from the ventilation slots.

Replacing the grinding disc

Fig. B

Worn or damaged grinding discs must be replaced

immediately.

Only use sharp and undamaged grinding

discs.

To remove the old grinding disc (9), proceed •

as described in the section

”Mounting and removing the grinding disc”.

To mount the new grinding disc (9), proceed •

as described in the section

”Mounting and removing the grinding disc”.

EN

9

Ferm

Replacing the carbon brushes

Fig. A

Remove the screws (3).•

Withdraw the carbon brushes from the •

machine and inspect them for wear.

Place the carbon brushes back in the brush •

holders provided.

Check that the copper contact on the carbon •

brushes makes good contact with the copper

part in the brush holder.

Replace the screws (3) and tighten them •

firmly.

Frequent use will cause the carbon

brushes to wear down. Regular

inspection, after every 30 hours of use, is

essential. If the brushes have worn down

to less than 4 mm, they need to be

replaced.

Warranty

Consult the enclosed warranty terms.

Environment

Disposal

The product, the accessories, and the

packaging must be sorted for

environmentally friendly recycling.

Only for EC countries

Do not dispose of power tools into domestic

waste. According to the European Guideline

2002/96/EC for Waste Electrical and Electronic

Equipment and its implementation into national

right, power tools that are no longer usable must

be collected separately and disposed of in an

environmentally friendly way.

EN

10 Ferm

EN

11

Ferm

EN

12 Ferm

EN

13

Ferm

Spare parts list

AGM1048 - FAG-115/500

Position Description No.

1 Flange key 204066

2 + 4 Flange set 204067

5 Guard for grinding 204068

5 Guard for cutting 300802

12 Bearing 806201

14 Big gear 204069

19 till 21 Spindle lock 204070

22 Auxiliary handle 204071

23 Pinion gear 204072

24 Bearing 800608

28 Rotor 204073

29 Bearing 800627

32 Stator 204074

40 + 46 Switch complete 204075

43 Carbon brush holder 204076

44 Carbon brush set 204077

45 Carbon brush cap 204078

EN

14 Ferm

Exploded view

15

Ferm

DECLARATION OF CONFORMITY

FAG-115/500, ANGLE GRINDER

(EN) We declare under our sole responsibility that this product

is in conformity and accordance with the following

standards and regulations:

(DE) Der Hersteller erklärt eigenverantwortlich, dass dieses

Produkt den folgenden Standards und Vorschriften

entspricht:

(NL) Wij verklaren onder onze volledige verantwoordelijk heid

dat dit product voldoet aan, en in overeenstem ming is

met, de volgende standaarden en reguleringen:

(FR) Nous déclarons sous notre seule responsabilité que ce

produit est conforme aux standards et directives suivants:

(ES) Declaramos bajo nuestra exclusiva responsabilidad que

este producto cumple con las siguientes normas y

estándares de funcionamiento:

(PT) Declaramos por nossa total responsabilidade de que este

produto está em conformidade e cumpre as normas e

regulamentações que se seguem:

(IT) Dichiariamo, sotto la nostra responsabilità, che questo

prodotto è conforme alle normative e ai regolamenti

seguenti:

(SV) Vi garanterar på eget ansvar att denna produkt upp fyller

och följer följande standarder och bestämmelser:

(FI) Vakuutamme yksinomaan omalla vastuullamme, että

tämä tuote täyttää seuraavat standardit ja säädökset:

(NO) Vi erklærer under vårt eget ansvar at dette produktet er i

samsvar med følgende standarder og regler:

(DA) Vi erklærer under eget ansvar, at dette produkt er i

overensstemmelse med følgende standarder og

bestemmelser:

(HU) Felelősségünkteljestudatábankijelentjük,hogyeza

termék teljes mértékben megfelel az alábbi

szabványoknakéselőírásoknak:

(CS) Nanašivlastnízodpovědnostprohlašujeme,žejetento

výrobekvsouladusnásledujícímistandardyanormami:

(SK) Vyhlasujemenanašuvýhradnúzodpovednosť,žetento

výrobok je v zhode a súlade s nasledujúcimi normami a

predpismi:

(SL) S polno odgovornostjo izjavljamo, da je ta izdelek v skla-

du in da odgovarja naslednjim standardom terpredpisom:

(PL) Deklarujemynawłasnąodpowiedzialność,żetenprodukt

spełniawymogizawartewnastępującychnormachi

przepisach:

(LT) Prisiimdamivisąatsakomybędeklaruojame,kadšis

gaminysatitinkažemiaupaminėtusstandartusarba

nuostatus:

(LV) Apgalvojamarvisuatbildību,kašisproduktsirsaskaņā

un atbilst sekojošiem standartiem un nolikumiem:

(ET) Deklareerime meie ainuvastutusel, et see toode on vasta-

vuses ja kooskõlas järgmiste standardite ja määrustega:

(RO) Declarămprinaceastacurăspundereadeplinăcă

produsulacestaesteînconformitatecuurmătoarele

standarde sau directive:

(HR) IzjavljujemopodvlastitomodgovornoĻśudajestrojem

ukladansaslijedeśimstandardimailistandardiziranim

dokumentima i u skladu sa odredbama:

(SR) Podpunomodgovornošćuizjavljujemodajeusaglašen

sasledećimstandardimailinormama:

(RU) Подсвоюответственностьзаявляем,чтоданное

изделиесоответствуетследующимстандартами

нормам:

(UK) Насвоювласнувідповідальністьзаявляємо,щодане

обладнаннявідповідаєнаступнимстандартамі

нормативам:

(EL) ¢ËÏÒÓÔ˘Ì¢‡ı˘Ó·fiÙÈÙÔÚÔ˚fiÓ·˘ÙfiÛ˘ÌʈÓ›ηÈ

ÙËÚ›ÙÔ˘˜·Ú·Î¿ÙˆÎ·ÓÔÓÈÛÌÔ‡˜Î·ÈÚfiÙ˘·:

EN60745-1, EN 60745-2-3, EN 55014-1, EN 55014-2, EN 61000-3-2,

EN 61000-3-3

2006/42/EC, 2002/95/EC, 2002/96/EC, 2004/108/EC, 2006/95/EC

Zwolle, 01-11-2010

J.A. Bakker-van Ingen

CEO Ferm BV

It is our policy to continuously improve our products and we therefore reserve the right to change the

product specification without prior notice.

Ferm BV • Lingenstraat 6 • 8028 PM • Zwolle The Netherlands

© 2010 Ferm B.V. 1012-03

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

Ferm AGM1048 Manual de utilizare

- Categorie

- Polizoare unghiulare

- Tip

- Manual de utilizare

în alte limbi

- English: Ferm AGM1048 User manual