Yamaha CS1D Manualul proprietarului

- Categorie

- Mixere audio

- Tip

- Manualul proprietarului

Owner’s Manual

FCC INFORMATION (U.S.A.)

1. IMPORTANT NOTICE: DO NOT MODIFY THIS UNIT! This product, when installed as indicated in the instructions contained in this manual, meets FCC

requirements. Modifications not expressly approved by Yamaha may void your authority, granted by the FCC, to use the product.

2. IMPORTANT: When connecting this product to accessories and/or another product use only high quality shielded cables. Cable/s supplied with this product MUST

be used. Follow all installation instructions. Failure to follow instructions could void your FCC authorization to use this product in the USA.

3. NOTE: This product has been tested and found to comply with the requirements listed in FCC Regulations, Part 15 for Class “B” digital devices. Compliance with

these requirements provides a reasonable level of assurance that your use of this product in a residential environment will not result in harmful interference with

other electronic devices. This equipment generates/uses radio frequencies and, if not installed and used according to the instructions found in the users manual, may

cause interference harmful to the operation of other electronic devices. Compliance with FCC regulations does not guarantee that interference will not occur in all

installations. If this product is found to be the source of interference, which can be determined by turning the unit “OFF” and “ON”, please try to eliminate the

problem by using one of the following measures: Relocate either this product or the device that is being affected by the interference. Utilize power outlets that are on

different branch (circuit breaker or fuse) circuits or install AC line filter/s. In the case of radio or TV interference, relocate/reorient the antenna. If the antenna lead-in

is 300 ohm ribbon lead, change the lead-in to coaxial type cable. If these corrective measures do not produce satisfactory results, please contact the local retailer

authorized to distribute this type of product. If you can not locate the appropriate retailer, please contact Yamaha Corporation of America, Electronic Service

Division, 6600 Orangethorpe Ave, Buena Park, CA 90620

The above statements apply ONLY to those products distributed by Yamaha Corporation of America or its subsidiaries.

* This applies only to products distributed by YAMAHA CORPORATION OF AMERICA. (Perchlorate)

This product contains a battery that contains perchlorate material.

Perchlorate Material—special handling may apply,

See www.dtsc.ca.gov/hazardouswaste/perchlorate.

This product contains a high intensity lamp that

contains a small amount of mercury. Disposal of

this material may be regulated due to environmen-

tal considerations.

For disposal information in the United States, refer

to the Electronic Industries Alliance web site:

www.eiae.org

(mercury)* This applies only to products distributed by

YAMAHA CORPORATION OF AMERICA.

* This applies only to products distributed by

YAMAHA CORPORATION OF AMERICA.

COMPLIANCE INFORMATION STATEMENT

(DECLARATION OF CONFORMITY PROCEDURE)

Responsible Party : Yamaha Corporation of America

Address : 6600 Orangethorpe Ave., Buena Park, Calif. 90620

Telephone : 714-522-9011

Type of Equipment : Control Surface

Model Name : CS1D

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1) this device may not cause harmful interference, and

2) this device must accept any interference received including interference

that may cause undesired operation.

See user manual instructions if interference to radio reception is sus-

pected.

(FCC DoC)

NEDERLAND / THE NETHERLANDS

• Dit apparaat bevat een lithium batterij voor geheugen back-up.

• This apparatus contains a lithium battery for memory back-up.

• Raadpleeg uw leverancier over de verwijdering van de batterij

op het moment dat u het apparaat ann het einde van de lev-

ensduur of gelieve dan contact op te nemen met de vertegen-

woordiging van Yamaha in uw land.

•For the removal of the battery at the moment of the disposal at

the end of life please consult your retailer or Yamaha repre-

sentative office in your country.

• Gooi de batterij niet weg, maar lever hem in als KCA.

• Do not throw away the battery. Instead, hand it in as small

chemical waste.

(lithium disposal)

ADVARSEL!

Lithiumbatteri—Eksplosionsfare ved fejlagtig

håndtering. Udskiftning må kun ske med batteri

af samme fabrikat og type. Levér det brugte

batteri tilbage til leverandoren.

VARNING

Explosionsfara vid felaktigt batteribyte. Använd

samma batterityp eller en ekvivalent typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti

asennettu. Vaihda paristo ainoastaan

laitevalmistajan suosittelemaan tyyppiin. Hävitä

käytetty paristo valmistajan ohjeiden

mukaisesti.

ii

Important

Read the following before operating the CS1D

Warnings

•

Do not allow water to enter this unit or allow the unit

to become wet. Fire or electrical shock may result.

•

Connect this unit’s power cord only to an AC outlet of

the type stated in this Owner’s Manual or as marked

on the unit. Failure to do so is a fire and electrical

shock hazard.

•

Do not place heavy objects, including this unit, on top

of the power cord. A damaged power cord is a fire and

electrical shock hazard. In particular, be careful not to

place heavy objects on a power cord covered by a car-

pet.

•

Do not modify the unit. Doing so is a fire and electri-

cal shock hazard.

•

Do not place a container with liquid or small metal

objects on top of this unit. Liquid or metal objects

inside this unit are a fire and electrical shock hazard.

Cautions

•

This unit has ventilation holes at the top and bottom

to prevent the internal temperature rising too high.

Do not block them. Blocked ventilation holes are a fire

hazard.

•

Since this device is heavy, please use an appropriate

number of people (two or more) when moving it.

•

Before moving the CS1D, you must be sure to lower

the display toward the back until it is fastened in posi-

tion.

•

Do not use the device or headphones for a long period

of time at a high or uncomfortable volume level, since

this can cause permanent hearing loss. If you experi-

ence any hearing loss or ringing in the ears, consult a

physician.

•

Do not apply oil, grease, or contact cleaner to the fad-

ers. Doing so may cause problems with electrical con-

tact or fader motion.

Operating Notes

•

The digital circuits of this unit may induce a slight

noise into nearby radios and TVs. If noise occurs, relo-

cate the affected equipment.

•

Using a mobile telephone near this unit may induce

noise. If noise occurs, use the telephone away from the

unit.

•

XLR-type connectors are wired as follows: pin 1:

ground, pin 2: hot (+), and pin 3: cold (–).

•

If the message “WARNING LOW BATTERY !” appears

when you turn on this unit, contact your dealer as

soon as possible about replacing the internal data

backup battery. The unit will still operate correctly,

but data other than the presets will be lost.

We recommend that you save the data on an ATA-

compatible PC flash storage card before replacing the

battery.

•

The performance of components with moving con-

tacts, such switches, rotary controls, faders, fans, and

connectors, deteriorates over time. The rate of deterio-

ration depends on the operating environment and is

unavoidable. Consult your dealer about replacing

defective components.

•

The CS1D is cooled by fan exhaust openings located

on its rear panel. Check these regularly and use a vac-

uum cleaner etc. to ensure that the openings do not

become clogged with dust. Before performing this

maintenance, you must turn off the POWER switch of

the PM1D power supply unit and make sure that the

CS1D is not operating.

•

The power must be turned on/off using the POWER

switch of the PW1D power supply unit. Do not turn

the power on/off by plugging in the power cable, or by

using a power strip or circuit breaker. Doing so may

cause malfunctions.

•

Do not rapidly turn on and off the POWER switch of

the PW1D power supply unit. Doing so may cause

excessive current to damage the system. You must

allow at least five seconds to elapse between power-on

and power-off.

Handling the included PM1D System Software disc

The included PM1D System Software Disc is CD-R media containing documentation and software for the PM1D.

A computer with a connected CD drive is required in order to use this documentation and software.

For details on the contents, refer to the documentation on the disc.

Please observe the following points when handling the disc.

Failure to do so may cause problems such as the recorded data being lost, the drive to malfunction, or the printed label to

become blurred.

•

Do not place the disc in locations of direct sunlight,

high temperature, or high humidity.

•

Do not touch either surface of the disc.

Hold the disc at the edges. Gently wipe dust or dirt off

of the recording surface of the disc.

Important

iii

•

Do not wipe the disc with chemicals or detergents.

•

Do not bend or drop the disc.

•

Use an air duster or cleaner to remove dust. Vigorously

rubbing the surface of the disc with a dry cloth may

scratch the disc.

•

Do not write on the disc or affix labels to it.

•

Keep water droplets or condensation off of the label

surface.

•

Yamaha Corporation makes no guarantee of a disc

that is rendered unreadable due to careless handling.

CS1D Exclusion of Certain Responsibility

Manufacturer, importer, or dealer shall not be liable for any incidental damages including personal injury or any other

damages caused by improper use or operation of the CS1D.

About the LCD display

The LCD screen built into the CS1D has the following characteristics. Please be aware that even if the following symp-

toms occur, this is not a malfunction or a defect.

•

Since the LCD display is manufactured with extremely

delicate technology, individual pixels may not display

correctly. (A pixel may be constantly lit or constantly

dark.)

•

The LCD screen may be affected by changes in the

ambient temperature.

•

Depending on the environment of use, you may notice

unevenness in brightness or small spots.

•

Since the LCD screen uses a cold cathode tube for a

backlight, the state of the display will gradually change

over time.

Cautions when handling the track pad

•

Place your hand and arm in a relaxed, natural posi-

tion, and operate the track pad by moving your finger

lightly across the surface or tapping it gently.

•

This device is designed to be operated with one finger.

It will not operate in the following situations.

1) When operated by a gloved finger

2) When operated with a pen, ballpoint pen, or pen-

cil etc.

3) When operated by two or more fingers

4) When operated with an object placed on it

•

The unit may not operate correctly if water droplets or

condensation are present on the surface, or if operated

using a soiled or sweaty finger. If condensation occurs,

dry the unit thoroughly, or wipe it dry before use.

•

To avoid malfunctions, please observe the following

cautions.

1) Do not drop objects on the unit, strike it, or sub-

ject it to strong physical shock.

2) Do not spill coffee, juice, or other liquids on the

unit.

•

Do not operate the unit with a pointed metal object

such as a pen, since this will damage the unit.

•

If the surface becomes soiled, wipe it clean with a dry

cloth. If the surface is severely soiled, wipe with a

moist cloth, and dry carefully before use.

•

Do not touch the surface while the por is being turned

on.

Trademarks

ADAT MultiChannel Optical Digital Interface is a trademark and ADAT and Alesis are registered trademarks of Alesis

Corporation. Tascam Digital Interface is a trademark and Tascam and Teac are registered trademarks of Teac Corpora-

tion. Windows and Windows NT are trademarks of Microsoft Corporation. Compact Flash is a trademark of SanDisk

Corporation. Yamaha is a trademark of Yamaha Corporation. All other trademarks are the property of their respective

holders and are hereby acknowledged.

Copyright

No part of the CS1D software or this

Owner’s Manual

may be reproduced or distributed in any form or by any means

without the prior written authorization of Yamaha Corporation.

© 2000 Yamaha Corporation. All rights reserved.

Yamaha website

http://www.yamaha.co.jp/product/proaudio/homeenglish

Yamaha manual Library

http://www2.yamaha.co.jp/manual/english/

Operating Manual

Operating Manual

(Start-up)

ii

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

About the “CS1D Operating Manual (Start-up)” . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Printing conventions in “CS1D Operating Manual (Start-up)”. . . . . . . . . . . . . . . . 1

Introducing the various components . . . . . . . . . . . . . . . . . . . . .2

Terms used in the “CS1D Operating Manual (Start-up)” . . . . . . . . . . . . . . . . . . . . 4

Connections (Standard mode). . . . . . . . . . . . . . . . . . . . . . . . . . .6

Connecting the console and engine (Standard mode) . . . . . . . . . . . . . . . . . . . . . . 6

Connecting an analog input/output unit to the engine (Standard

mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting a digital input/output unit to the engine (Standard mode) . . . . . . . . 9

Connections (Mirror mode). . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Connecting the console and engines (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . 10

Connecting an analog input/output unit to the engines (Mirror mode) . . . . . . . 12

Connecting a digital input/output unit to the engines (Mirror mode) . . . . . . . . 13

Turning on the power and verifying the connections . . . . . . .14

Turning on the power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Checking the status of each device (Standard mode). . . . . . . . . . . . . . . . . . . . . . 15

Checking the engine (Standard mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Checking the analog input unit (Standard mode) . . . . . . . . . . . . . . . . . . . . . . 16

Checking the analog output unit (Standard mode) . . . . . . . . . . . . . . . . . . . . . 17

Digital input/output unit (Standard mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Checking the status of each device (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . 18

Engines (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Checking the analog input unit (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . 19

Checking the analog output unit (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . 20

Checking the digital input/output unit (Mirror mode) . . . . . . . . . . . . . . . . . . . 21

Basic settings (Standard mode). . . . . . . . . . . . . . . . . . . . . . . . .22

Selecting the operation mode (Standard mode) . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting the word clock (Standard mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Contents

iii

Basic settings (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Selecting the operation mode (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting the word clock (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Checking the operation of input units . . . . . . . . . . . . . . . . . . . 30

Preparations for checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connect the monitor system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connect an input source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Patch the input unit to an input channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Monitor the input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Checking the operation of an output unit . . . . . . . . . . . . . . . . 38

Preparations for checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connect the monitor system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connect an input source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Patch the input unit to an input channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Patch the STEREO A channel to an output unit . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Send the input signals of input channels 1/2 to the STEREO bus . . . . . . . . . . . . 44

Turn off the power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1

Introduction

About the “CS1D Operating Manual (Start-up)”

The “CS1D Operating Manual (Start-up)” is an introductory manual that explains how to connect the various compo-

nents of the PM1D system and verify that the PM1D system is operating correctly.

When starting up the PM1D system for the first time, or if you have changed the configuration of the system such as

when the PM1D system has been moved to another location and/or re-connected, we recommend that you follow the

procedure described in this manual to verify that the system is operating correctly.

•

This manual explains only the minimum operations.

For details on operating the PM1D system, please

refer to “CS1D Operating Manual (Basic operation)”

•

For details on the specifications and functionality of

the engine (DSP unit DSP1D-EX {DSP1D}) and I/O

units, please refer to the owner’s manual included

with each device.

•

For details on the function and operation of the con-

trollers and connectors found on the top panel, rear

panel, and front panel of the console (CS1D), refer to

“CS1D Reference Manual (Hardware).”

•

For details on the software in the display screen of

the console (CS1D), refer to “CS1D Reference Man-

ual (Software).”

Screen shots shown in this manual are taken from a

prototype. Please be aware that they may differ

slightly from the actual screens on your unit.

Printing conventions in “CS1D Operating Manual (Start-up)”

•

Differences between the 96 channel model and 48

channel model

In general, the “CS1D Operating Manual (Start-up)”

is written with the 96 channel model PM1D system

(the model with the DSP1D-EX as the engine) in

mind. Where the functionality of the 96 channel

model differs from the 48 channel model (the model

with the DSP1D as the engine), the functionality of

the 48 channel model is enclosed in curly brackets { }.

•

Standard mode and Mirror mode

The PM1D system has two operation modes (ele-

ments that determine system structure and connec-

tion method); “Standard mode” in which one

console is connected to one engine, and “Mirror”

mode in which one console is connected to two

engines of which only one is used.

Be aware that the mode used by the PM1D system

will depend not only on the number of engines, but

also on the type of connections and on the internal

settings.

Explanations that apply only to

Standard mode

will

be indicated by the following symbol.

Explanations that apply only to

Mirror mode

will be

indicated by the following symbol.

The PM1D system version 1.0 does not support any

other operation mode (i.e., other than Mirror

mode) in which two engines are used.

•

Distinguishing between the controls of the CS1D

and the on-screen knobs/buttons

Names of controls (switches, encoders, faders) on the

top panel, rear panel, and front panel of the CS1D

are enclosed in square brackets [ ] in order to distin-

guish them from the knobs and buttons etc. that are

displayed in the screen.

Example

: Tu rn on the [TO ST] switch.

(This indicates an operation on the top panel of the

CS1D.)

Example

: Click the BASIC button.

(This indicates an operation in the display screen.)

•

Va r ious icons

The following icon is used to call your attention to

various tips for operation or to reference pages.

The following icon is used to indicate particularly

important items or operations that you must be

aware of.

DSP

x1x1

DSP

x2x2

Hint

2

Introducing the various components

The PM1D system consists of the following types of components. (The components that are actually included will differ

depending on your system.)

Engine (DSP1D-EX {DSP1D})

This is the DSP unit that performs the majority of the

audio processing in the PM1D system, such as audio sig-

nal input/output, mixing, and effects. There are two

models of engine: the

96 channel DSP1D-EX

, and the

48 channel DSP1D

.

Console (CS1D)

The mixing operations, scene memory/library opera-

tions, and various editing operations of the PM1D sys-

tem are performed from this console.

Power supply (PW1D)

This power supply provides power to the console.

Analog input unit (AI8)

This is an input unit that inputs analog audio signals to

the engine, and can accommodate up to eight analog

input cards.

The following types of cards can be installed in the AI8.

•

Mic/line input card (LMY2-ML)

•

AD card (LMY4-AD)

The following models of AI8 are available, depending on

the type of analog input cards that are installed.

•

AI8-ML8

A unit with eight mic/line input cards installed

•

AI8-AD8

A unit with eight AD cards installed

•

AI8-ML4AD4

A unit with four mic/line input cards + four AD

cards installed

Cards can be installed in the AI8 only by a Yamaha

service engineer. The user must never attempt to

install a card himself.

Analog output unit (AO8)

This is an output unit that outputs analog audio signals

from the engine, and can accommodate eight DA cards

(LMY4-DA).

Cards can be installed in the AO8 only by a Yamaha

service engineer. The user must never attempt to

install a card himself.

Digital input/output unit (DIO8)

This unit performs input/output of ADAT, Tascam, and

AES/EBU format digital audio signals and input/output

of analog audio signals to and from the engine of the

PM1D system. Each DIO8 unit can accommodate up to

eight digital I/O cards or analog I/O cards.

The following types of card can be installed.

POWER

ON/ OFF

A B

ENGINE ID

1 2

CONTROL I/O

48CH 96CH

INPUT

CONFIGURATION

POWER

ON OFF

INPUT UNIT NO.

PHANTOM MASTER

ON

OFF

+48V

POWER

ON/ OFF

12345678

ANALOG INPUT BOX

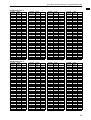

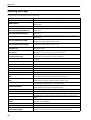

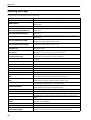

Card Format Input Output

MY8-TD TASCAM 8 IN 8 OUT

MY8-AT ADAT 8 IN 8 OUT

MY8-AE AES/EBU 8 IN 8 OUT

MY8-AD ANALOG IN 8 IN —

MY4-AD ANALOG IN 4 IN —

MY4-DA ANALOG OUT — 4 OUT

AP8AD* ANALOG IN 8 IN —

AP8DA*

*: Manufactured by Apogee Corporation

* As of September 1, 2000

ANALOG OUT — 8 OUT

1234567

OUTPUT UNIT NO.

INPUT SELECTOR

A

B

POWER

ON/ OFF

8

ANALOG OUTPUT BOX

I/O UNIT ID

PORT B SELECTOR

5-8

1-4

POWER

ON/ OFF

Introducing the various components

3

It is not possible to install and use a total of five or

more AP8AD/AP8DA cards. Also, if you are using

AP8AD/AP8DA cards simultaneously with MY8-

AD/MY4-AD/MY4-DA cards, there are restrictions

on the number of cards, as described below. Never

exceed the allowable number of cards, since

attempting to use a greater number of cards than

allowed may damage the DIO8 due to excessive

current. If you are not using AP8AD or AP8DA

cards, or if you are using AP8AD or AP8DA cards

simultaneously with an MY8-TD/MY8-AT/MY8-

AE card, there is no limitation on the number of

MY8-TD/MY8-AT/MY8-AE cards that can be used.

[AP8AD] +

[AP8DA] cards

used

[MY8-AD] +

[MY4-AD] +

[MY4-DA]

cards used

[MY8-TD] +

[MY8-AT] +

[MY8-AE] cards

used

Total 0 cards Up to a total of 8 cards

Total 1 card Up to 6 cards

Up to the number

of vacant DIO8

slots

Total 2 cards Up to 4 cards

Up to the number

of vacant DIO8

slots

Total 3 cards Up to 2 cards

Up to the number

of vacant DIO8

slots

Total 4 card Up to 1 card

Up to the number

of vacant DIO8

slots

Total 5 or more

cards cannot

be used

——

CS1D Operating Manual (Start-up)

4

Terms used in the “CS1D Operating Manual (Start-up)”

Of the specialized terms used in operating the CS1D, this section will explain the terms that appear in “CS1D Operating

Manual (Start-up).” For a more detailed explanation of terms, refer to “CS1D Operating Manual (Basic Operation).”

•

Display

This refers to the LCD display located in the upper

center of the CS1D console. When you wish to

change an internal setting of the CS1D, you can recall

the appropriate screen in the display, and use the

buttons or knobs in the display to edit the setting.

•

Pointer

The arrow shown in the display is called the

“pointer,” and is used to select the object that you

wish to modify. You can move the pointer by pressing

your finger on the track pad (located in the data

entry block) and dragging it up/down/left/right.

•

Cursor

The red frame shown in the display is called the “cur-

sor.” An on-screen item will be enclosed by the cur-

sor to indicate that this item is selected for

modification.

•

Click

“Click” refers to the action of placing the pointer on

a specific item in the display, and pressing the left or

right switch of the track pad (located in the data

entry block). This action is used to turn an on-screen

button on/off, or to move the cursor to a specific

item.

Using the [CURSOR] switches (located in the data

entry block) to move the cursor to a specific item and

then pressing the [ENTER] switch will have the same

result as clicking on that item.

Hint

As alternative ways to perform this action, you can

use a mouse connected to the MOUSE connector of

the CS1D, or use the arrow keys and ENTER key of a

keyboard connected to the KEYBOARD connector of

the CS1D.

[CURSOR] switches

Tra ck pad

Left switch[ENTER] switches

Display

Data entry block

Right switch

Pointer

Cursor

Left switch

Click

Mouse left click

Right switch

Click

Mouse right click

Introducing the various components

5

•

Drag

“Drag” refers to the action of placing the pointer

over a specific object on the screen, and holding

down the left or right switch while you slide your fin-

ger left/right/up/down across the track pad.

This action is used to continuously adjust a knob or

slider in the screen, or to move a specific item to

another location.

Hint

As an alternative way to perform this action, you can

use a mouse connected to the MOUSE connector of

the CS1D.

Tra ck pad

Drag

Drag

Mouse

While pressing

6

Connections (Standard mode)

This section explains connections for Standard mode, in which one console (CS1D) is connected to one engine (DSP1D-

EX {DSP1D}).

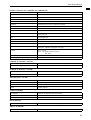

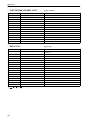

Connecting the console and engine (Standard mode)

The following diagram shows typical connections between the console and engine for Standard mode.

1

Digital input/output connections

Use the included D-sub half pitch 68 pin cable to

connect the DIGITAL I/O ENGINE A connector of

the console to the CONSOLE I/O connector of the

engine.

These connectors transmit and receive multi-channel

digital audio signals.

The console and engine each have two identical digi-

tal input/output connectors, numbered 1 and 2.

These two sets of connectors are completely identi-

cal, and the system will operate normally if just one

set is connected. However, you may connect both 1

and 2 so that one of them can be used as a backup.

You must connect the identically-numbered con

-

nectors of the console and engine to each other. If

differently-numbered connectors are connected to

each other, the system will not function correctly.

This method of connection is recommended for

most cases.

DSP

x1x1

1

3

POWER SUPPLY (PW1D)

ENGINE A

2

ENGINE A

DC POWER

INPUT A

IN OUT

IN OUT

CONSOLE (CS1D)

ENGINE A

(DSP1D-EX{DSP1D})

CONTROL

I/O

CONSOLE

I/O

DIGITAL

I/O

CONTROL

I/O

1IN531

2 OUT 6 4 2

OUTPUT

CONSOLE

I/O

CASCADE

DIGITAL I/O

2

CONSOLE

1 2121

ENGINE B

DIGITAL I/O

ENGINE A

Console (CS1D)

Engine

(DSP1D-EX {DSP1D})

Connections (Standard mode)

7

Hint

If both digital input/output connectors 1 and 2 are

connected, connector 1 will be given priority when

the power is turned on.

If the word clock stops being supplied from either

connector 1 or 2 (whichever is the currently-used

connector), the receiving device will automatically

switch to the other connector.

•

Use only Yamaha-manufactured D-sub half pitch 68

pin cables to connect the digital input/output con-

nectors. Operation cannot be guaranteed if any other

cables are used.

•

If you need a cable of a different length than the

included D-sub half pitch 68 pin cable, please con-

tact your dealer.

2

Control input/output connections

Use BNC cables (50

Ω

) to connect the CONTROL I/

O ENGINE A IN connector of the console to the

CONTROL I/O OUT connector of the engine, and

the CONTROL I/O ENGINE A OUT connector of

the console to the CONTROL I/O IN connector of

the engine.

These connectors transmit and receive control sig-

nals between the console and engine.

The console and engine each have two identical sets

of connectors, numbered 1 and 2.

These two sets of connectors are completely identi-

cal, and the system will operate normally if just one

set is connected. However, you may connect both 1

and 2 so that one of them can be used as a backup.

This method of connection is recommended for

most cases.

You must connect the identically-numbered con

-

nectors of the console and engine to each other. If

differently-numbered connectors are connected to

each other, the system will not function correctly.

Hint

If both control input/output connectors 1 and 2 are

connected, connector 1 will be given priority when

the power is turned on.

If the currently-used control output connector stops

functioning correctly, the receiving device will auto-

matically switch to the other connector.

3

Power supply connections

Use the included special cable to connect the DC

POWER INPUT connector of the console to the DC

OUTPUT connector of the PW1D power supply.

The rear panel of the console has two DC POWER

INPUT connectors, A and B.

If you are using only one power supply, you may con-

nect it to either DC POWER INPUT connector.

Hint

You can also connect two power supplies to the two

DC POWER INPUT connectors A and B. If this con-

nection method is used, the PM1D system will con-

tinue to operate even if one of the power supplies

should unexpectedly fail, since the other power sup-

ply will continue to supply power to the system.

22

22

IN

OUT

IN

2

OUT

IN

1

OUT

THRU

PC

CONTROL

WORD CLOCK

TIME CODE IN

GPI

RS-422

REMOTE

IN

OUT

OFF

ON

RS-232-C

USB

75Ω

MIDI CONTROL I/O

CONSOLE

CONSOLE ENGINE B ENGINE A

IN

1

2

OUT

IN

OUT

IN

1

2

OUT

IN

OUT

IN

1

2

OUT

IN

OUT

CONTROL I/O

Console (CS1D)

Engine

(DSP1D-EX {DSP1D})

CS1D Operating Manual (Start-up)

8

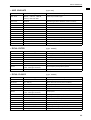

Connecting an analog input/output unit to the engine (Stan-

dard mode)

The following diagram shows a common way of making connections between the engine and analog input/output units

for Standard mode.

1

Analog input unit AI8 connection

Connect the OUTPUT A connector of the AI8 analog

input unit to one of the INPUT 1–INPUT 10 con-

nectors of the engine. Set the CONTROL PORT

switch (located on the rear panel of the AI8) to the A

position.

2

Analog output unit AO8 connection

Connect the INPUT A connector of the AO8 analog

output unit to one of the OUTPUT 1–OUTPUT 6

connectors of the engine. Set the INPUT SELECTOR

switch (located on the front panel of the AO8) to the

A position.

Hint

An AI8 analog input unit can be connected to any

INPUT connector of the engine, and the number of

that INPUT connector will be the ID number of that

unit. Similarly, an AO8 analog output unit can be

connected to any OUTPUT connector of the engine,

and the number of that OUTPUT connector will be

the ID number of that unit.

Be careful not to connect inputs and outputs in

reverse. If such a connection is made, the unit will

not be recognized and cannot be controlled.

ANALOG OUTPUT BOX ANALOG OUTPUT BOX

ANALOG INPUT BOXANALOG INPUT BOX

INPUT 1

INPUT 2

INPUT A INPUT AOUTPUT A OUTPUT A

OUTPUT 1

OUTPUT 2

12

ENGINE A

(DSP1D-EX{DSP1D})

AI8 (ID=2) AI8 (ID=1) AO8 (ID=1) AO8 (ID=2)

CONTROL PORT

Switch = A

INPUT SELECTOR

Switch = A

CONTROL PORT

Switch = A

INPUT SELECTOR

Switch = A

Connections (Standard mode)

9

Connecting a digital input/output unit to the engine (Standard

mode)

When connecting a DIO8 digital input/output unit to the engine in Standard mode, the method will depend on whether

you use only slots 1–4 (of the DIO8’s slots 1–8) or slots 1–4 as well as slots 5–8.

1

If input/output cards are installed only in DIO8

slots 1–4

The following diagram shows example connections

for when input/output cards are connected only to

slots 1–4 of the DIO8.

Connect the OUTPUT A connector of the digital

input/output unit to one of the INPUT 1–10 connec-

tors of the engine, and connect the INPUT A connec-

tor of the digital input/output unit to one of the

OUTPUT 1–6 connectors of the engine. In this case,

set the PORT B SELECTOR switch (located on the

front panel of the DIO8) to the 5-8 position.

2

If input/output cards are also installed in DIO8

slots 5–8

The following diagram shows example connections

for when input/output cards are installed in DIO8

slots 1–4 and also in slots 5–8.

Connect the OUTPUT connectors A/B of the digital

input/output unit to the INPUT 1–10 connectors of

the engine, and connect the INPUT connectors A/B

of the digital input/output unit to OUTPUT 1–6

connectors of the engine. In this case, set the PORT B

SELECTOR switch (located on the front panel of the

DIO8) to the 5-8 position.

Hint

The DIO8 digital input/output unit can be con-

nected to any INPUT connector/OUTPUT connec-

tor of the engine. The DIO8 will automatically select

a control connector according to the status of con-

nections, and the connector number of the engine

connected to that connector will be displayed in the

LED display as the unit ID. In the example shown

above, the INPUT 1 connector number is the unit ID

number.

Be careful not to connect inputs and outputs in

reverse. If such a connection is made, the unit will

not be recognized and cannot be controlled.

When using an MY8-AT card to handle ADAT for

-

mat signals, synchronization may tend to be lost

easily, depending on the device that is connected.

For more reliable synchronization, we recommend

that the word clock for the combination of digital

audio equipment you are using be taken from other

than the ADAT format connector.

DIO8 (ID=1)

PORT B SELECTOR=5–8

INPUT 1

OUTPUT A INPUT A

OUTPUT 1

ENGINE A

(DSP1D-EX{DSP1D})

DIO8 (ID=1)

PORT B SELECTOR=5–8

OUTPUT INPUT

ENGINE A

(DSP1D-EX{DSP1D})

INPUT 2

INPUT 1

OUTPUT 1

OUTPUT 2

BBAA

10

Connections (Mirror mode)

This section explains connections for Mirror mode, in which one console (CS1D) is connected to two engines (DSP1D-

EX {DSP1D}).

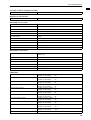

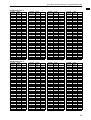

Connecting the console and engines (Mirror mode)

The following diagram shows typical connections between the console and engines for Mirror mode.

1

Digital input/output connections

Use the included D-sub half pitch 68 pin cables to

connect the DIGITAL I/O ENGINE A connector of

the console to the CONSOLE I/O connector of engine

A, and the DIGITAL I/O ENGINE B connector of the

console to the CONSOLE I/O connector of engine B.

These connectors transmit and receive multi-channel

digital audio signals.

•

Use only Yamaha-manufactured D-sub half pitch 68

pin cables to connect the digital input/output con-

nectors. Operation cannot be guaranteed if any other

cables are used.

•

If you need cables of a different length than the

included D-sub half pitch 68 pin cables, please con-

tact your dealer.

•

The console and engines A/B each have two identical

sets of digital input/output connectors, numbered 1

and 2.

These two sets of connectors are completely identi-

cal, and the system will operate normally if just one

set is connected. However, you may connect both 1

and 2 so that one of them can be used as a backup.

This method of connection is recommended for

most cases.

DSP

x2x2

3

4

POWER SUPPLY (PW1D)

DC POWER

INPUT A

ENGINE B

(DSP1D-EX{DSP1D})

12

ENGINE A ENGINE B

ENGINE A ENGINE B

IN OUT IN OUT

CONSOLE (CS1D)

ENGINE A

(DSP1D-EX{DSP1D})

CONTROL

I/O

CONSOLE

I/O

CONSOLE

I/O

DIGITAL

I/O

CONTROL

I/O

CONTROL

I/O

IN OUT

IN OUT

Clock Generator

WORD

CLOCK IN

WORD

CLOCK IN

WORD

CLOCK IN

1IN5

2 OUT 6

CONSOLE

I/O

CASCADE

2

CONSOLE

1 2121

ENGINE B

DIGITAL I/O

ENGINE A

1IN5

2 OUT 6

CONSOLE

I/O

CASCADE

Console

(CS1D)

Engine B Engine A

Connections (Mirror mode)

11

Hint

If both digital input/output connectors 1 and 2 are

connected, connector 1 will be given priority when

the power is turned on.

If the word clock stops being supplied from either

connector 1 or 2 (whichever is the currently-used

connector), the receiving device will automatically

switch to the other connector.

2 Control input/output connections

Use BNC cables (50Ω) to connect the CONTROL I/

O ENGINE A IN and OUT connectors of the console

to the CONTROL I/O OUT and IN connectors of

engine A. In the same way, connect the CONTROL I/

O ENGINE B IN and OUT connectors of the console

to the CONTROL I/O OUT and IN connectors of

engine B. These connectors transmit and receive

control signals between the console and engines A/B.

The console and engines A/B each have two identical

sets of connectors, numbered 1 and 2. These two sets

of connectors are completely identical, and the sys-

tem will operate normally if just one set is connected.

However, you may connect both 1 and 2 so that one

of them can be used as a backup.

This method of connection is recommended for

most cases.

Hint

If both control input/output connectors 1 and 2 are

connected, connector 1 will be given priority when

the power is turned on.

Control output connectors 1/2 will always output the

same signals. If the currently-used control output

connector stops functioning correctly, the receiving

device will automatically switch to the other connec-

tor.

You must connect the identically-numbered con

-

nectors of the console and engine to each other. If

differently-numbered connectors are connected to

each other, the system will not function correctly.

3

Power supply connections

Use the included special cable to connect the DC

POWER INPUT connector of the console to the DC

OUTPUT connector of the PW1D power supply.

The rear panel of the console has two DC POWER

INPUT connectors, A and B. If you are using only

one power supply, you may connect it to either DC

POWER INPUT connector.

You can also connect two power supplies to the two

DC POWER INPUT connectors A and B. If this con-

nection method is used, the PM1D system will con-

tinue to operate even if one of the power supplies

should unexpectedly fail, since the other power sup-

ply will continue to supply power to the system.

4

Word clock connections

Use BNC cables (75

Ω

) to connect the clock output

connector of an external clock generator to the

WORD CLOCK IN connector of the console, and to

the WORD CLOCK IN connectors of engines A/B.

Connect the word clock transmitting and receiving

devices in a one-to-one relationship, and turn on the

75

Ω

screen for the receiving device.

The word clock transmission/reception circuit is

designed with one-to-one connection in mind. For

this reason, if you connect multiple receiving

devices to a single clock transmission connector,

performance may be impaired and the system may

fail to operate correctly.

If you cannot avoid using this type of connection,

turn on the 75

Ω

switch for one of the receiving

devices, and turn off the 75

Ω

switches for all

remaining devices.

In Mirror mode, you can also switch to the other

engine manually if the currently-used engine expe-

riences difficulties.

In order to minimize the clock switching time in

such cases, we recommend that you supply a word

clock from an external clock generator to the con-

sole and to engines A/B.

Of course, switching will occur even without this

type of supply method.

22

22

IN

OUT

IN

2

OUT

IN

1

OUT

THRU

PC

CONTROL

WORD CLOCK

TIME CODE IN

GPI

RS-422

REMOTE

IN

OUT

OFF

ON

RS-232-C

USB

75Ω

MIDI CONTROL I/O

CONSOLE

22

22

IN

OUT

IN

2

OUT

IN

1

OUT

THRU

PC

CONTROL

WORD CLOCK

TIME CODE IN

GPI

RS-422

REMOTE

IN

OUT

OFF

ON

RS-232-C

USB

75Ω

MIDI CONTROL I/O

CONSOLE

CONSOLE ENGINE B ENGINE A

IN

1

2

OUT

IN

OUT

IN

1

2

OUT

IN

OUT

IN

1

2

OUT

IN

OUT

CONTROL I/O

Console (CS1D)

Engine B Engine A

CS1D Operating Manual (Start-up)

12

Connecting an analog input/output unit to the engines (Mirror

mode)

The following diagram shows a common way of making connections between the engine and analog input/output units

for Mirror mode.

1

Analog input unit AI8 connection

Connect the OUTPUT A connector of the AI8 analog

input unit to one of the INPUT 1–INPUT 10 con-

nectors of engine A, and connect the OUTPUT B

connector of the AI8 to one of the INPUT 1–INPUT

10 connectors of engine B.

•

When using Mirror mode, OUTPUT connectors A

and B of the AI8 must be connected to the identi-

cally-numbered INPUT connector of engines A and

B. Be aware that if these are connected to differently-

numbered INPUT connectors, the content of the

input signals will change when you switch between

engines A and B.

•

When using Mirror mode, leave the CONTROL

PORT switch of the AI8 in the A position as the

default setting.

2

Analog output unit AO8 connection

Connect the INPUT A connector of the AO8 analog

output unit to one of the OUTPUT 1–OUTPUT 6

connectors of engine A. Connect the INPUT B con-

nector of the AO8 to one of the OUTPUT 1–OUT-

PUT 6 connectors of engine B.

•

When using Mirror mode, INPUT connectors A and

B of the AO8 must be connected to the identically-

numbered OUTPUT connector of engines A and B.

Be aware that if these are connected to differently-

numbered OUTPUT connectors, the content of the

output signals will change when you switch between

engines A and B.

•

When using Mirror mode, leave the INPUT SELEC-

TOR switch of the AO8 in the A position as the

default setting.

•

Be careful not to reverse the input and output. If you

do so, the unit will not be recognized, and cannot be

controlled.

ANALOG OUTPUT BOX ANALOG OUTPUT BOX

ANALOG INPUT BOXANALOG INPUT BOX

INPUT 1

INPUT 2

INPUT A INPUT AOUTPUT A OUTPUT A

INPUT B INPUT BOUTPUT B OUTPUT B

OUTPUT 1

INPUT 1

OUTPUT 1

OUTPUT 2

INPUT 2

OUTPUT 2

12

ENGINE A

(DSP1D-EX{DSP1D})

ENGINE B

(DSP1D-EX{DSP1D})

AI8 (ID=2) AI8 (ID=1) AO8 (ID=1) AO8 (ID=2)

WORD

CLOCK IN

WORD

CLOCK

IN

WORD

CLOCK IN

WORD

CLOCK IN

WORD

CLOCK IN

Clock Generator

CONTROL

PORT

Switch = A

CONTROL

PORT

Switch = A

INPUT

SELECTOR

Switch = A

INPUT

SELECTOR

Switch = A

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

Pagina se încarcă...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

-

226

226

-

227

227

-

228

228

-

229

229

-

230

230

-

231

231

-

232

232

-

233

233

-

234

234

-

235

235

-

236

236

-

237

237

-

238

238

-

239

239

-

240

240

-

241

241

-

242

242

-

243

243

-

244

244

-

245

245

-

246

246

-

247

247

-

248

248

-

249

249

-

250

250

-

251

251

-

252

252

-

253

253

-

254

254

-

255

255

-

256

256

-

257

257

-

258

258

-

259

259

-

260

260

-

261

261

-

262

262

-

263

263

-

264

264

-

265

265

-

266

266

-

267

267

-

268

268

-

269

269

-

270

270

-

271

271

-

272

272

-

273

273

-

274

274

-

275

275

-

276

276

-

277

277

-

278

278

-

279

279

-

280

280

-

281

281

-

282

282

-

283

283

-

284

284

-

285

285

-

286

286

-

287

287

-

288

288

-

289

289

-

290

290

-

291

291

-

292

292

-

293

293

-

294

294

-

295

295

-

296

296

-

297

297

-

298

298

-

299

299

-

300

300

-

301

301

-

302

302

-

303

303

-

304

304

-

305

305

-

306

306

-

307

307

-

308

308

-

309

309

-

310

310

-

311

311

-

312

312

-

313

313

-

314

314

-

315

315

-

316

316

-

317

317

-

318

318

-

319

319

-

320

320

-

321

321

-

322

322

-

323

323

-

324

324

-

325

325

-

326

326

-

327

327

-

328

328

-

329

329

-

330

330

-

331

331

-

332

332

-

333

333

-

334

334

-

335

335

-

336

336

-

337

337

-

338

338

-

339

339

-

340

340

-

341

341

-

342

342

-

343

343

-

344

344

-

345

345

-

346

346

-

347

347

-

348

348

-

349

349

-

350

350

-

351

351

-

352

352

-

353

353

-

354

354

-

355

355

-

356

356

-

357

357

-

358

358

-

359

359

-

360

360

-

361

361

-

362

362

-

363

363

-

364

364

-

365

365

-

366

366

-

367

367

-

368

368

-

369

369

-

370

370

-

371

371

-

372

372

-

373

373

-

374

374

-

375

375

-

376

376

-

377

377

-

378

378

-

379

379

-

380

380

-

381

381

-

382

382

-

383

383

-

384

384

-

385

385

-

386

386

-

387

387

-

388

388

-

389

389

-

390

390

-

391

391

-

392

392

-

393

393

-

394

394

-

395

395

-

396

396

-

397

397

-

398

398

-

399

399

-

400

400

-

401

401

-

402

402

-

403

403

-

404

404

-

405

405

-

406

406

-

407

407

-

408

408

-

409

409

-

410

410

-

411

411

-

412

412

-

413

413

-

414

414

-

415

415

-

416

416

-

417

417

-

418

418

-